Liquid Hydrogen Rocket Fuel Definition, Cost, Impact and Benefits

Liquid hydrogen rocket fuel is liquefied hydrogen which has favorable characteristics like low molecular weight and high energy density, that make it suitable for use as a rocket propellant.

This article discusses liquid hydrogen rocket fuel definition, suitability, cost, environmental impact, and benefits, as follows;

-Definition of Liquid Hydrogen Rocket Fuel

-The Suitability of Liquid Hydrogen as a Rocket Fuel

-Cost of Liquid Hydrogen Rocket Fuel

-Environmental Impact of Liquid Hydrogen as a Rocket Fuel

-Benefit(s) of Liquid Hydrogen Rocket Fuel

Definition of Liquid Hydrogen Rocket Fuel

Liquid hydrogen rocket fuel is a high-energy density liquid that is composed mainly of hydrogen that has been liquefied under pressurized, cryogenic (low temperature) conditions [2].

Generally, rocket fuel is made of solid, liquid or gaseous energy resources that have high output of energy per unit mass, in order to meet the demands for propulsion and sustained flight.

The development and optimization of rocket fuels has been an important topic in the field of space exploration, and has influenced several modifications in space craft technology.

Solid rocket fuel is made of materials like aluminium powder, polybutadiene and ammonium perchlorate; where aluminium is the main fuel and the other components act as binder and oxidant respectively [3].

NASA uses gaseous rocket fuel in the form of hydrogen gas, which is highly optimized for energy density, and stored at low temperature.

The choice of hydrogen as a rocket fuel comes mainly from its high capacity of energy output, and is also favored by factors such as the light-weight of hydrogen as propulsion cargo.

Generally, the kind of fuel used in rockets is one which can deliver tremendous amount of energy and burn with high intensity, while having relatively low weight and highly-compressible mass (for fluids). Such fuel can be derived through processing, from conventional fossil fuels.

Rocket fuel can be made from fossil fuels like petroleum, as is the case for hydrogen, which can be produced by steam reforming of hydrocarbons. This method (steam reforming) is most common for large-scale petroleum-based hydrogen production.

Gasification can be also used to extract hydrogen from hydrocarbons and other organic materials like biomass.

In some cases, rocket fuel can be made by intensive refining of petroleum to yield rocket-grade petroleum (a processed form of kerosene), also referred to as RP-1 [1].

The Suitability of Liquid Hydrogen as a Rocket Fuel

Liquid hydrogen is used as a rocket fuel for two main reasons, which are its high-energy density, and its low molecular-weight.

The energy density of liquid hydrogen is approximately 120 MJ/kg, which is nearly three-times that of gasoline, at 44 MJ/kg [4].

This allows hydrogen fuel to serve as a powerful energy storage medium that enables rocket crafts to carry tremendous amounts of energy with relatively-low gravitational pull.

Liquid hydrogen also has a high specific impulse, which is a measure of the efficiency with which energy in a propellant fuel is converted to thrust as the fuel burns in an engine, and is usually abbreviated as Isp and measured in seconds (s).

For liquid hydrogen, specific impulse Isp is about 460 s [8]. This thrust efficiency is very important to enable rockets and similar crafts to enter orbit.

NASA uses liquid hydrogen in some of its rockets and launch systems, including the Delta III and Atlas rockets, due to the high specific impulse and light-weight propulsion needed by these systems. It must be recalled that gaseous hydrogen is more prominent as a craft propellant in NASA's operations.

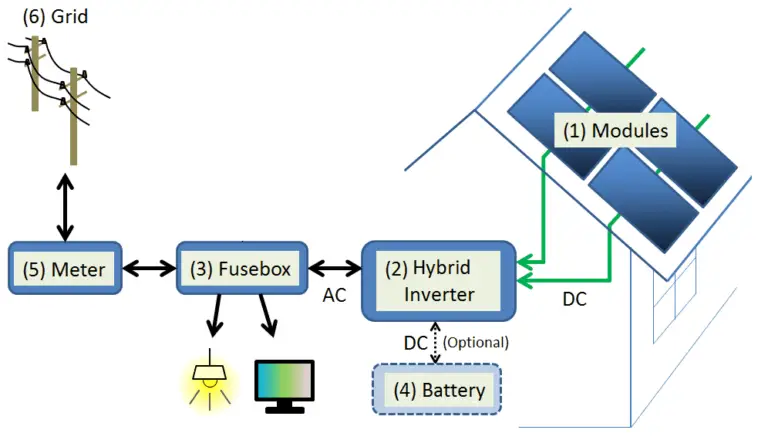

NASA gets liquid hydrogen from a number of industrial suppliers based mostly in North America, and most of who produce the fuel from hydrocarbons by steam-reforming.

The liquid hydrogen is kept by cryogenic storage in well-insulated vessels at around -423°F, and handled carefully to prevent explosion hazards.

Suitability of Liquid Hydrogen as a Rocket Fuel: Cryogenic-Insulated Storage (Credit: NASA/SBSEIPEL 2020)

Cost of Liquid Hydrogen Rocket Fuel

The cost of liquid hydrogen production ranges from 1.25 USD/kg to 3.50 USD/kg on average [5]. This range is based on steam reforming of natural gas, which is the most common method used.

Efforts are being made to produce green hydrogen at lower cost for rockets, by solar-powered electrolysis.

Additional cost of liquid hydrogen comes from its handling, which includes transport and storage. These requirements are usually added to the production cost when developing a hydrogen energy budget.

Liquid hydrogen is more expensive than gasoline, mainly because of the energy and equipment required to liquefy hydrogen.

Environmental Impact of Liquid Hydrogen as a Rocket Fuel

Rocket fuel is bad for the environment when its production and/or usage produces unfavorable environmental impacts like pollution and climate change-facilitation.

The disadvantage of liquid hydrogen rocket fuel is based on how it affects the environment in its production stage.

During actual combustion and energy release, liquid hydrogen is clean, and produces no significant emission or toxic byproduct [7]. The main byproduct of the actual combustion of liquid hydrogen is water, which occurs because of the use of oxygen to facilitate combustion.

However, during its production, liquid hydrogen can affect the environment significantly.

Emissions from liquid hydrogen rocket fuel in the production stage include include carbon dioxide (CO2) produced as hydrocarbon substrate breaks down to yield hydrogen.

The amount of CO2 that is emitted by a rocket launch is up to 50 tonnes and may reach 300 tonnes [6]. This carbon can be very persistent in the atmosphere, and could contribute to climate change.

A rocket launch also causes some degree of air pollution. The amount of pollution created by rocket launching is approximately 1,000 tons per year, of soot. This is especially the case where rocket-grade petroleum (RP-1), or refined kerosene, is used as rocket fuel.

However, space rockets do not much to global warming at a global scale, especially when compared to other contributors. Their contribution is far less than 0.1 percent, with some estimates placing the value as low as 6.0 × 10^-6 percent.

Benefit(s) of Liquid Hydrogen Rocket Fuel

Liquid hydrogen is a good rocket fuel because it burns with high intensity, high specific impulse, low combustion emission, and light weight.

Some benefits or advantages of liquid hydrogen as a rocket fuel are listed below;

1). Low molecular weight

2). High energy density

3). Low combustion emission

4). Abundant occurrence of hydrogen on Earth

5). Space-efficient production and consumption

Conclusion

Liquid hydrogen rocket fuel is simply liquefied hydrogen that is used to provide high specific impulse with low emission, in rocket propulsion engines.

The cost of liquid hydrogen production is between 1.25 USD/kg and 3.50 USD/kg on average.

Benefits or advantages of liquid hydrogen rocket fuel are; low molecular weight, high energy density, low combustion emission, abundant occurrence of hydrogen on Earth, space-efficient production and consumption.

References

1). Andersen, P. C.; Bruno, T. J. (2005). "Thermal Decomposition Kinetics of RP-1 Rocket Propellant." Industrial & Engineering Chemistry Research 44(6). Available at: https://doi.org/10.1021/ie048958g. (Accessed 27 February 2023).

2). Aziz, M. (2021). "Liquid Hydrogen: A Review on Liquefaction, Storage, Transportation, and Safety." Energies 14(18):5917. Available at: https://doi.org/10.3390/en14185917. (Accessed 27 February 2023).

3). Aziz, A.; Khairuddin, W. A. W. (2011). "A Study of Basic Aluminized Propellants Characteristics." Applied Mechanics and Materials 110-116. Available at: https://doi.org/10.4028/www.scientific.net/AMM.110-116.1321. (Accessed 27 February 2023).

4). Aziz, M.; Oda, T.; Kashiwagi, T. (2019). "Comparison of liquid hydrogen, methylcyclohexane and ammonia on energy efficiency and economy." Energy Procedia 158:4086-4091. Available at: https://doi.org/10.1016/j.egypro.2019.01.827. (Accessed 26 February 2023).

5). Clarance, F. (2022). "Unlocking Hydrogen Full Potential as ASEAN Future Energy." IOP Conference Series Earth and Environmental Science 997(1):012017. Available at: https://doi.org/10.1088/1755-1315/997/1/012017. (Accessed 26 February 2023).

6). Gammon, K. (2021). "How the billionaire space race could be one giant leap for pollution." Available at: https://www.theguardian.com/science/2021/jul/19/billionaires-space-tourism-environment-emissions. (Accessed 26 February 2023).

7). Han, D.; Roh, T-S.; Huh, H.; Lee, H. J. (2022). "Development Trend of Liquid Hydrogen-Fueled Rocket Engines (Part 2: Core Technologies)." International Journal of Aeronautical and Space Sciences ( IF 1.233 ) . Available at: https://doi.org/10.1007/s42405-022-00518-8. (Accessed 26 February 2023).

8). Silvera, I. F.; Cole, J. (2010). "Metallic hydrogen: The most powerful rocket fuel yet to exist." Journal of Physics Conference Series 215(1):012194. Available at: https://doi.org/10.1088/1742-6596/215/1/012194. (Accessed 26 February 2023).