Electric Motor Definition, History, and Working Principle Explained

An electric motor is a device which produces a rotary motion from electricity. This article discusses electric motor meaning, history and working principle, as outlined below;

-Electric Motor Meaning: 5 Ways to Define an Electric Motor

-History of the Electric Motor: Some of the Major Milestones

-Electric Motor Working Principle

-How Does an Electric Motor Work

Electric Motor Meaning: 5 Ways to Define an Electric Motor

An electric motor is a power-driven device which converts electricity to mechanical energy [6].

Also often referred to as the electric engine, the electric motor is particularly important for its role in converting electricity to mechanical energy.

This concept of electric-mechanical energy conversion can further be used to describe the electric motor, as done below;

An electric motor is an electromechanical device that functions based on the electromagnetic principle, to produce a mechanical force from electric current.

If the electric motor functions based on electromagnetic principles, its operation can be considered similar to the process of electricity generation by a generator.

Such an analogy must be clarified and/or elaborated to establish a clear understanding of the nature of the electric motor. This is done in the following definition;

An electric motor is a device which produces a mechanical torque when a perpendicular electric current in a conductor, interacts with a magnetic field [1].

The mechanical torque usually occurs in form of rotary motion of a shaft. Magnitude of torque and speed of rotation may vary, according to the characteristics of the electric motor.

There may also be differences in the internal configuration of electric motors, such as the relative positions of components. Such differences can be used to categorize these devices into various groups.

Another factor which can be used to describe an electric motor is the type of current electricity that is used to power the device;

An electric motor is a device which is powered by electricity in the form of Direct Current (DC) from rectifiers and batteries; or Alternating Current from generators and inverters; and which converts this electricity to mechanical energy in the form of rotary motion.

As the above definition implies, an electric motor may be powered by electricity from AC or DC sources [12].

Lastly, electric motor meaning can be outlined based on the possible applications of the device.

This is an important perspective, because the electric motor has been a major component of many technological advances in the field of modern electricity.

An electric motor is an electromechanical, electromagnetic device that is used to produce mechanical energy from electricity, in electric vehicles, vacuum cleaners, water pumps, computer printers and sewage treatment facilities, among others.

History of the Electric Motor: Some of the Major Milestones

Origin of the electric motor dates back to the sixteenth century when, during the 1740s, Scottish scientist and monk Andrew Gordon, described a model of an electrostatic device, with working principles that were portrayed through experiments [16].

This simplistic model proposed by Gordon is the oldest known precursor to the electric motor s it is exists today.

Other scientists like Benjamin Franklin, Joseph Henry and Michael Faraday, subsequently made further contribution to the development of electric motor technology, through various studies and experiments in electromagnetism and electric current conversion.

One of the principles which supported the development of the electric motor concept, is Coulomb’s Law [21].

First discovered by Henry Cavendish in the year 1771 [5], the principle was published later in 1785, based on independent findings by Charles-Augustin de Coulomb [10].

A major achievement in the efforts to improve the electric motor was made in 1799, when Alessandro Volta invented the electrochemical battery [15].

This was a milestone as it enabled the production of relatively-high voltage on a consistent basis. Prior to the invention, electrostatic devices were not practically usable since it was impossible to supply the required voltage for their operation.

Hans Christian Ørsted was a pioneer of the discovery of electromagnetism.

In 1820, he experimented with electric currents and discovered their capability to produce a magnetic force field under certain conditions [2].

Shortly afterward, André-Marie Ampère described the electromagnetic phenomenon based on interaction between electric currents and magnetic fields [8].

Michael Faraday provided one of the earliest illustrations of the electromechanical effect of electromagnetism. In 1821, he showed that a magnetic field can induce rotary motion in a charged conductor [20].

Peter Barlow, an English physicist and mathematician, constructed the first practical electromechanical device in 1822 [7].

This device was called the ‘Barlow’s Wheel’ and was designed based on findings by Faraday and other scientists. While it was technically similar to the modern electric motor, the device had shortcomings in terms of the efficiency of electromechanical conversion.

Anyos Jedlik, a Hungarian physicist, invented the commutator, as a result of experiments conducted between 1827 and 1828 [18]. This component helped to improve the rotation efficiency of electric motors.

Jedlik’s work led to the modern design of the electric motor, which comprises of commutator, rotor and stator.

Based on the commutator design, William Sturgeon built the first DC electric motor in 1832 [4].

After studying the mechanisms of electromagnetic induction and electromechanical conversion, German scientist Heinrich Friedrich Emil Lenz documented his findings on the reciprocal nature of electromagnetism, which he published in 1833 [11].

These findings were useful in outlining the similarities between the electric motor and electric generator, and served as a basis for further development of both devices.

The first practical electric motor was invented by Moritz Jacobi in 1834 [9]. Although there are other attributions for the invention of the electric motor, Jacobi’s model demonstrated the full potential of the device in terms of mechanical power, energy efficiency and reliability.

American inventors Thomas and Emily Davenport built an improved model of the DC electric motor in 1837 [19], based on the concept earlier produced by William Sturgeon.

Because of its dependence on batteries for DC supply, and due to the limitations of battery technology at the time, Davenport’s model was not successful or practically usable. It was easily outshone by the more efficient design by Jacobi, whose mechanical power was illustrated by using the device to propel machines like boats [14].

Commercial use of the electric motor commenced soon after Jacobi’s invention of the high-power motor.

Christopher Becker and Sibrandus Stratingh designed an electric car to run based on electric motor technology, in 1835 [3].

Another critical modification of the electric motor system is credited to Antonio Pacinotti, who introduced the ring armature model in 1864.

The model, which comprises of symmetrical coils of conductor material linked to the commutator, helped to achieve electromechanical conversion under stable conditions.

For most of the nineteenth century, electric motor technology was affected by its dependence on direct current, DC. Because of the technical limitations of DC supply, practical usability of the electric motor was limited to low-demand functions.

These limitations were addressed in 1887, when Nikola Tesla invented the AC induction motor [17]. After the invention was patented in 1888, it soon became an integral component of many important electrical systems.

Since the development and widespread adoption of the AC induction motor, electric motor technology has been repeatedly modified to improve its efficiency and performance. It has also been used as a key component of machines in various industries.

Electric Motor Working Principle

An electric motor works through a three-stage process which includes electricity supply, electromagnetic induction, and electromechanical conversion.

Each of these stages is discusses below;

1). Electricity Supply in an Electric Motor

Electricity supply is the first step in the operational process for an electric motor.

Current may be supplied in either of two forms; Direct Current (DC) and Alternating Current (AC). These forms of current supply can be used to categorize electric motors.

DC electric motor usually receives its electricity from a battery.

Due to the relative simplicity of the DC motor, the battery terminals are often connected to the rotor (mechanical component) of the device.

For the AC electric motor, electric current is supplied from an electric generator or rectifier.

Unlike the DC motor, the current source in AC motors is not usually connected to the rotor. Rather, it is linked to an intermediate component that resolves the effect of current reversals and alternations.

2). Electromagnetic Induction in an Electric Motor

Electromagnetic induction is the second step in the process of operation of an electric motor.

Basically, electric motors work on the basis of electromagnetic principle. Due to the flow of electric charges through a conductor in the device, a magnetic field is created.

This magnetic field which is created as a result of current flow in an electric motor, is essential to the electromechanical conversion and creation of electromotive force.

3). Electromechanical Conversion

Electromechanical conversion occurs when the electromagnetic field in an electric motor, induces rotary motion of a moveable component, which is usually connected to the conductor.

It is essentially the conversion of electricity input, to mechanical energy.

The mode of electromechanical conversion may differ for DC and AC motors.

In DC motors, electromechanical conversion is a relatively simple process, because the electric charges flow in a consistent, uniform direction.

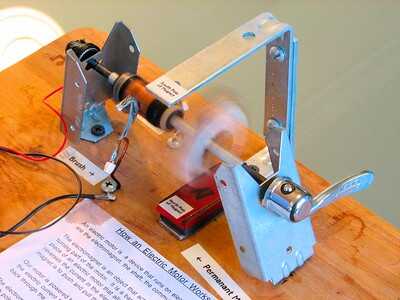

One of the parts of an electric motor is a permanent magnet [13].

The temporary electromagnetic field produced by the charged conductor, interacts with the permanent magnetic field surrounding this magnet.

As a result of this interaction, the conductor is influenced by the varying effects of both fields, which causes it to rotate, thereby producing mechanical energy.

While the direct current in a DC motor creates a unidirectional electromagnetic field which interacts with the permanent magnetic field to produce consistent rotary motion, this is not the case for AC motors.

Because the current in an AC electric motor is always alternating, a mechanism is usually provided to rectify this alternating effect so as to produce a consistent and unidirectional electromechanical force.

This component is the commutator, which occurs in the form of a split metal ring with each segment connected to opposite ends of the conductor coil.

AC current is supplied to the electric motor through two terminals called brushes, which are in loose contact with the commutator.

Because of the loose contact of these terminals, and the spilt configuration of the commutator, when AC current flows into the electric motor, its alternating effect is continuously reversed as the conductor rotates, thereby ensuring that rotation remains unidirectional and consistent.

Commutators may also be used in DC electric motors.

Conclusion

An electric motor is a device that produces mechanical energy from an electric current.

Origin of the electric motor dates back to the eighteenth century, and involves various efforts in the fields of current electricity, electromagnetism, electrostatics, and electrical engineering.

Electric motors work by the principle of electromagnetic induction in a closed system, and operates based on a three-step process, as follows

- Electricity Supply

- Electromagnetic Induction

- Electromechanical Conversion

References

1). Ather, H. (2020). “How to Calculate DC Motor Torque.” Available at: https://sciencing.com/calculate-dc-motor-torque-7816902.html. (Accessed 7 May 2022).

2). Brain. R.; Cohen, R. S.; Knudsen, O. (2007).”Hans Christian Ørsted And The Romantic Legacy In Science: Ideas, Disciplines, Practices.” Boston Studies in the Philosophy and History of Science. Available at: https://doi.org/10.1007/978-1-4020-2987-5. (Accessed 7 May 2022).

3). Bellis, M. (2019). “The History of Electric Vehicles Began in 1830.” Available at: https://www.thoughtco.com/history-of-electric-vehicles-1991603. (Accessed 8 May 2022).

4). El-Shahat, A. (2018). “Introductory Chapter: Electric Machines for Smart Grids and Electric Vehicles Applications.” Electric Machines for Smart Grids Applications – Design, Simulation and Control. Available at: https://doi.org/10.5772/intechopen.80659. (Accessed 8 May 2022).

5). Falconer, I. J. (2016). “No actual measurement … was required: Maxwell and Cavendish’s null method for the inverse square law of electrostatics.” Studies In History and Philosophy of Science Part A 65-66(4). Available at: https://doi.org/10.1016/j.shpsa.2017.05.001. (Accessed 7 May 2022).

6). Ferreira, F. J. T. E.; Silva, A. M.; Aguiar, V. P. B.; Pontes, R. S. T. (2018). “Overview of Retrofitting Options in Induction Motors to Improve Their Efficiency and Reliability.” IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), Palermo – Italy, Volume: . Available at: https://doi.org/10.1109/EEEIC.2018.8493887. (Accessed 7 May 2022).

7). Friedrich, L. (2020). “Isogeometric analysis of nonlinear eddy current problems.” Available at: https://doi.org/10.6100/5074ed73-fcec-4a93-8a5c-699abcf6e896. (Accessed 7 May 2022).

8). Godfrey, M. (2015). “Mathematical Theory of Electrodynamic Phenomena by Andre-Marie Ampere.” Available at: https://doi.org/10.13140/RG.2.1.2303.8164. (Accessed 7 May 2022).

9). Grigoriev, N. D. (2020). “Boris S. Jacobi.” World of Transport and Transportation 17(4):284-300. Available at: https://doi.org/10.30932/1992-3252-2019-17-4-284-300. (Accessed 8 May 2022).

10). Helmenstine, A. M. (2020). “Chemistry Definitions: What are Electrostatic Forces?” Available at: https://www.thoughtco.com/definition-of-electrostatic-forces-604451. (Accessed 7 May 2022).

11). Jain, M. K. (2020). “Why Faraday’s research is revolutionary to start the era of Electrical Engineering?” Available at: https://www.railelectrica.com/basics-of-electrical-engineering/why-faradays-research-is-revolutionary-to-start-the-era-of-electrical-engineering/. (Accessed 8 May 2022).

12). Karatzaferis, I. C.; Lampropoulos, L. S.; Tatakis, E. C. (2011). “Efficiency improvement in DC and AC motor powered electric vehicles.” Proceedings of the 2011-14th European Conference on Power Electronics and Applications (EPE 2011). Available at: https://www.researchgate.net/publication/261420073_Efficiency_improvement_in_DC_and_AC_motor_powered_electric_vehicles. (Accessed 7 May 2022).

13). Koch, S.; Peter, M.; Fleischer, J. (2017). “Lightweight Design and Manufacturing of Composites for High-performance Electric Motors.” Procedia CIRP 66:283-288. Available at: https://doi.org/10.1016/j.procir.2017.03.274. (Accessed 8 May 2022). :

14). Molinas, M.; Monti, A. (2017). “The Marine Electrical Revolution: Battery Power at Sea [About This Issue].” IEEE Electrification Magazine 5(3):2-3. Available at: https://doi.org/10.1109/MELE.2017.2718822. (Accessed 8 May 2022).

15). Piccolino, M. (2000). “The bicentennial of the Voltaic battery (1800-2000): The artificial electric organ.” Trends in Neurosciences 23(4):147-51. Available at: https://doi.org/10.1016/S0166-2236(99)01544-1. (Accessed 7 May 2022).

16). Rotich, T. (2016). “Dynamic Model of a DC Motor-Gear-Alternator (MGA) System.” Asian Research Journal of Mathematics 1(4):1 – 16. Available at: https://doi.org/10.9734/ARJOM/2016/28948. (Accessed 7 May 2022).

17). Skjong, E.; Rødskar, E.; Molinas, M.; Johansen, T. A.; Cunningham, J. J. (2015). “The Marine Vessel’s Electrical Power System: From its Birth to Present Day.” Proceedings of the IEEE 103(12):2410 – 2424. Available at: https://doi.org/10.1109/JPROC.2015.2496722. (Accessed 8 May 2022).

18). Subudhi, P. S.; Krithiga, S. (2020). “Wireless Power Transfer Topologies used for Static and Dynamic Charging of EV Battery: A Review.” International Journal of Emerging Electric Power Systems 21(1). Available at: https://doi.org/10.1515/ijeeps-2019-0151. (Accessed 7 May 2022).

19). Tweney, D. (2010). “Feb. 25, 1837: Davenport Electric Motor Gets Plugged In.” Available at: https://www.wired.com/2010/02/0225davenport-electric-motor-patent/. (Accessed 8 May 2022).

20). Weisse, K.; Brauer, H.; Ziolkowski, M.; Toepfer, H. (2011). “Modelling and simulation of a simple homopolar motor of Faraday’s type.” FACTA UNIVERSITATIS Series Electronics and Energetics 24(2):221-242. Available at: https://doi.org/10.2298/FUEE1102221B. (Accessed 7 May 2022).

21). Wistrom, A.; Khachatourian, A. V. M. (2002). “Coulomb motor by rotation of spherical conductors via the electrostatic force.” Applied Physics Letters 80(15):2800-2801. Available at: https://doi.org/10.1063/1.1470259. (Accessed 7 May 2022).