Carbon Capture and Storage Technology Explained: Meaning and Methods

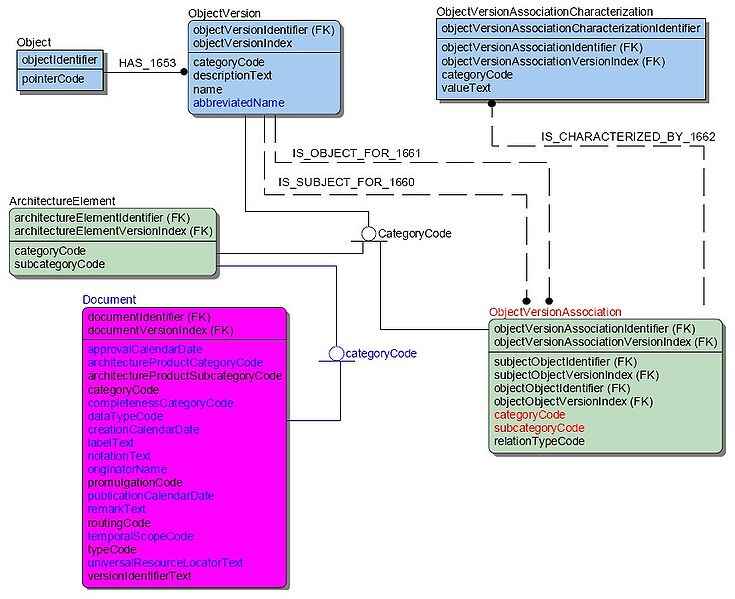

Carbon capture and storage is a branch of technology that tackles climate change and environmental degradation by capturing and storing carbon dioxide, thereby preventing this greenhouse gas from causing global warming.

In the world today, issues related to sustainable development, the environment, global warming, and climate change, have all revealed the importance of carbon capture technology.

As an element, it is one of the most significant contributors to climate change.

This article discusses the use of carbon capture technology to eliminate carbon from the atmosphere. It includes the following important aspects;

1). Meaning Carbon Capture and Storage Technology (CCS)

2). Carbon Capture, Utilization, and Storage (CCUS)

3). How can we Differentiate between both technologies? Difference CCS and CCUS

4). How does Carbon Capture Technology Work? The basic Mechanism of CCS

5). Permafrost and Carbon Storage

6). Global Application of Carbon Capture Technology

7). Carbon Capture Technology and Climate Change

8). Difficulties and Challenges

9). Policies and Regulations related to Carbon Capture and Storage Technology

10). Criteria which Determine the Quality of Carbon Capture Technology

11). What is Needed to Improve and Optimize Carbon Capture Technology

12). Some Important Carbon Capture Companies

Definition of Carbon Capture and Storage Technology

Carbon capture and storage (CCS) is simply a method and process by which carbon dioxide (CO2) is captured and stored instead of being released immediately and directly into the atmosphere [24].

In another definition, Carbon capture and storage (CCS) is a process which involves capturing carbon dioxide that is produced from industrial activity and power generation, and storing this CO2 to prevent its direct emission into the atmosphere.

Overview of what Carbon Capture Technology is about

Carbon Capture and Storage (CCS) is a potentially effective means of reducing carbon emissions into the atmosphere. Its main area of relevance is related to the fact that it can help in addressing environmental challenges on Earth today [9]. Such challenges include atmospheric pollution, heatwaves, global warming, and climate change.

Basically, CCS involves three main stages, namely; the capture of carbon dioxide (CO2), the transport of the captured carbon dioxide, and its storage [28].

Capture of CO2 is usually done at power generation plants or other industrial outlets at which it is produced. These outlets include cement and steel production facilities. Following its transport from the point of capture, the carbon dioxide may be stored at great depth, underground.

We may consider CCS technology to be potentially effective to reduce the emissions of CO2 in energy-driven systems. As will be mentioned later in this article, facilities which are equipped with CCS are able to capture most of the CO2 that they produce.

Carbon Capture, Utilization, and Storage (CCUS)

Although the more common practice is to capture, transport, and store carbon dioxide, there are yet a few exceptions.

Rather than being stored at depth underground, the captured CO2 can be put to use in some cases. This includes manufacturing and industrial maintenance applications. The practice of using captured CO2 is described with the term; Carbon Capture, Utilization, and Storage (CCUS).

Utilizing CO2, provides the advantage of reducing, delaying, or effectively managing its chances of return into the atmosphere. While some applications help to permanently store CO2 away from the atmosphere, others help reduce the need for direct use of fossil fuels.

A notable use of captured CO2, can be found in the field of Petroleum Engineering. Carbon dioxide is often sold to oil and gas operators. to be used in Enhanced Oil Recovery (EOR) [14]. This serves as an incentive to the development of carbon capture technology, since it provides revenue for CCS facility operators.

Enhanced oil recovery using CO2, is carried out, basically, by injecting large volumes of CO2 into oil and gas reservoirs to provide pressure for the extraction of petroleum.

While this is perhaps the most established use of captured carbon dioxide, other uses exist, which are being investigated and modified. An example of such is the supply of CO2 as a growth-catalyst for algae. These alga are later used in producing biofuel for some industrial and commercial applications [26].

How can we Differentiate between both technologies? Difference CCS and CCUS

As we can observe in the two acronyms, the main difference between them is ‘Utilization.’

This implies that asides the practice of utilizing captured CO2, CCS and CCUS are essentially the same technology. There is simply a little more elaboration in the approach of CCUS, whereby, rather than being stored away at once, or released into the atmosphere, CO2 is put to more beneficial use, which may involve converting it to concrete, biofuel or plastic.

It is important for us to note that this article fully addresses both CCS and CCUS, although with more emphasis on the former.

How does Carbon Capture and Storage Technology Work? The basic Mechanism of CCS

As we have earlier mentioned, the implementation of CCS technology at any industrial facility or power plant involves entails three basic steps; which are Capture, Transportation, and Storage.

Carbon Capture

This is the first and perhaps most important step in the overall CCS process. A number of important technologies exist, which are used in carbon capture. These include;

1). Absorption

2). Multiphase Absorption

3). Membrane

4). Adsorption

5). Oxy-fuel combustion

6). Chemical-looping combustion

7). Cryogenic Separation

8). Calcium looping

Among the carbon capture technologies listed above, Absorption is perhaps the most prominent [31]. It is carried out mainly using amines, and has been the most successful for practical, industrial application.

Details of Carbon Capture by Absorption

The basic principle behind carbon capture by absorption, is to bring the gas in contact with a chemical which we can call the ‘absorbent.’

An absorbent may be a pure solution or a chemical mixture, which is able to physically dissolve CO2. The absorption column is usually maintained at required pressure and temperature. Absorbents are generally required to have distinctive properties that allow them to react only with CO2, while the remaining gases may pass through unaffected.

Categories or Types of Carbon Capture

The capture of CO2 is simply its separation from other industrially-produced gases, like those generated at natural gas and coal plants, as well as cement and steel production facilities.

As we have already seen, various technologies may be utilized in carbon capture. However, these technologies can be generally grouped into three distinct categories, namely;

* Post-Combustion Capture Technology

* Pre-Combustion Capture Technology

* Oxy-fuel Combustion Capture Technology

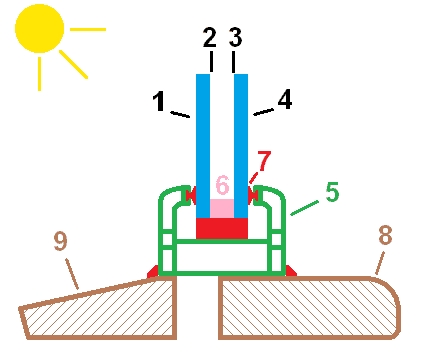

Post-Combustion Carbon Capture Technology

As the term implies, this form of technology separates CO2 from industrially-produced gases, after the combustion process in industrial engines has been completed.

We can interpret this in much simpler terms by understanding that Post-Combustion carbon capture involves the removal, separation, or ‘capture,’ of carbon dioxide which exits from the exhaust of a combustion engine, after the combustion process [27].

Therefore, Post-Combustion applies various mechanisms to remove the CO2 from flue gases resulting from the burning of fossil fuels. Based on this, we may also observe that Post-Combustion is more often applicable- and applied -to power plants and systems driven by fossil fuels like natural gas, oil or coal.

Flue gases produced from fossil fuel combustion in industrial and power-generating engines, typically include water vapor, nitrogen, sulfur dioxide and CO2 [32]. Although the process might seem complex, Post-Combustion is most convenient of all available technologies. This is simply because it can be deployed at pre-existing and new power plants alike.

The main challenges or disadvantages of Post-Combustion carbon capture include the fact that it requires relatively large equipment and can reduce the effectiveness and efficiency of turbines [11].

Pre-Combustion Carbon Capture Technology

Just as in the case pf Post-Combustion technology, we can understand the concept of Pre-Combustion based on the term itself.

Pre-Combustion carbon technology simply involves the separation or capture of carbon dioxide, before the completion of the combustion process in an industrial engine or power plant [7].

In order to achieve Pre-Combustion, fossil fuel is usually gasified and the CO2 is separated before use.

Oil, natural gas, or coal, is heated in oxygen and steam, and this produces what is known as ‘synthesis gas,’ or syngas. Syngas gas is dominantly comprised of hydrogen, carbon monoxide (CO), and carbon dioxide (CO2).

CH4 + 2O2 – CO2 + 2H2O

Subsequent reactions during the heating process result in carbon dioxide (CO2) and hydrogen (H2). The carbon dioxide can be isolated from this mixture in a relatively easy manner.

Pre-Combustion has the advantage of being relatively efficient as a carbon-capture approach, especially in comparison to Post-Combustion [31]. However, it is not as flexible as other technologies.

This is solely due to the reason that it cannot easily be incorporated into old industrial facilities, but may only be applied to new facilities, as a result of extremely high cost involved in carrying out the former.

Oxy-fuel-Combustion Carbon-Capture Technology

You might also be able to predict the mechanism of Oxy-fuel-Combustion carbon capture, based on the term itself.

Oxy-fuel-Combustion carbon capture involves the burning of fossil fuels in a mixture of gas which is dominated by oxygen [1]. The result of this combustion is a flue gas similar to the mixture in Pre-Combustion carbon capture process; comprising of mainly water (H2O) and carbon dioxide (CO2).

The CO2 can then be isolated by cooling and compression of the H2O content of the flue gas [27]. The use of an oxygen-rich combustion environment helps to produce high concentration of CO2 emission and this makes the capture process much easier.

Oxy-fuel-Combustion carbon capture has the advantage that it can be applied to both new and old power plants and industrial facilities [12]. However, it has two main drawbacks. One of these is the fact that it is relatively expensive. The other is that its application and feasibility for large scale facilities and processes, is doubtful.

Transport

Following the separation and capture of CO2, it is compressed into its liquid state, and transported.

The main options for transport of captured CO2 include road (in tankers), rail, sea (in ships and shuttle tanks), and pipelines [10].

Pipeline transport is the most commonly used so far, for transporting carbon dioxide to the site of storage. The reason for its dominant usage is mainly its flexibility relative to other methods of CO2 transport.

Pipelines can be used in virtually any environment, and may be installed on the surface, in the subsurface, or under the sea. The use of pipelines also reduces the risk of different forms of transport-related hazards.

We can understand the effectiveness and suitability of pipelines as a means of transport when we observe that they are the most used method for transporting other important industrial materials, such as oil and gas, water, and chemical waste [15].

In developed countries like the United States, pipelines are a major infrastructure, covering several thousands of miles across the region. In order to transport CO2, these pipelines can be linked to power-generation plants or processing outlets where the captured gas is emitted.

The purity and physicochemical properties of the CO2 in pipelines may vary, based on the nature of the plant to which the pipeline is connected, and the maintenance of the pipeline itself.

Multiple methods can also be used to transport CO2. For example, the CO2 may first be transported via pipeline, from which it would be subsequently transferred to a tanker. However, such an approach increases the rick of leakage and escape of the gas into the atmosphere.

Carbon Storage

The CO2 which has been captured, may subsequently be pumped into geologic rock formations underground, for storage [19]. While this form of storage is expected to be permanent, there are still pathways through which the stored CO2 may return to the atmosphere.

In the process of storage, CO2 may be pumped at depths of at least 1km. This is done in order to find suitable conditions for the confinement of the gas. The geologic formation may be coalbeds, depleted oil and gas reservoirs, saline aquifers, or other porous formations.

Permafrost and Carbon Storage

‘Permafrost’ refers to earth material that remains at temperatures no higher than 0°C or 32°F naturally, for a period of at east two years [11].

In recent years, permafrost has become even more important, especially with regards to issues of climate change [4].

This is mainly because it is now known that permafrost areas contain up to 1.7 trillion tons of carbon, which is stored in the frozen soil and rock material. Given the current conditions of global warming and defrosting (thawing) of glaciers in polar regions, there are enquiries concerning the fate of the trapped carbon.

Outline of Methods and Typical Conditions

Conditions of Carbon Capture

In order to fully and effectively understand the conditions and methods of carbon capture, it is necessary to group the sources of carbon into two categories. These categories include mobile and stationary sources. Examples of the mobile sources are automobiles and airplanes. Examples of stationary are factories and power generation plants.

There are currently no well-developed technologies for capturing CO2 from mobile sources. This means that our discussion will be centered primarily on CO2 from stationary sources, as given below;

Carbon Capture at Low Concentration from Stationary Sources

At low concentration, the process of carbon capture becomes more difficult and expensive [5].

As a result of this, carbon capture has been mostly restricted to highly concentrated flue gas streams. These include the gaseous emissions from coal-fired power plants and similar facilities.

However, with the introduction of less carbon-producing fuels like natural gas, CO2 emissions have been significantly reduced in terms of concentration, compared to coal. Given the importance of achieving negative or net-zero emissions, efforts are being made to improve on technologies for carbon capture at low concentration. The most used method for carbon capture at low concentration is adsorption. This is often achieved using Amines as the primary adsorbent.

Carbon Capture at High Concentration from Stationary Sources

As we have earlier mentioned, a classic example of carbon capture at high concentration is the capture of carbon from a coal-fired power plant.

The removal of CO2 at high concentration is less expensive than at low concentration. However. the regeneration of adsorbent, as well as the compression and transport of CO2 produced, usually demands large amounts of energy.

To overcome the excessive demand for energy in carbon capture, other methods have been introduced, such as Integrated Gasification Combined Cycle (IGCC) which converts fuel into syngas, and separates the CO2 in the gas from hydrogen (H2).

Conditions of Carbon Storage: Where the Captured CO2 is Stored

As we have already mentioned, carbon capture focuses on the ultimate storage of carbon dioxide (CO2) in regions or reservoirs that are away from the atmosphere.

Different applicable ‘reservoirs’ have been proposed for this purpose. They include geologic formations, subsea or ocean terrain, or well-maintained reservoirs on land [8].

Of all these proposed options, the use of geologic formations for CO2 storage has proved to be most efficient, effective, feasible and reliable. It basically involves injecting large volumes of the CO2 directly into underground porous formations.

Examples of such formations have been listed earlier in this article. They include deep saline aquifers, coal seams, and depleted oil and gas reservoirs.

Other means of carbon storage are associated with significant challenges. For example, on-land storage presents the problem of short-term retention and slow formation of carbonates [25].

Subsea (in the ocean) storage is also problematic, because large amounts of CO2 in the ocean may result in high degree of acidity and high ocean temperature, both of which are potentially harmful to marine organisms.

The storage of carbon dioxide in underground formations has been carried out in various parts of the world, so far. One of such places is the UK, where saline aquifers have been used as sites for carbon storage. Again as earlier mentioned, these formations are usually at depths of at least 1km underground.

Conditions and Methods of Carbon Utilization: Best Approaches

Carbon utilization is driven solely by the idea that carbon dioxide which has been captured, can be treated as a valuable and useful commodity. Some ways in which CO2 can be utilized, are discussed briefly below;

1). Enhanced Oil Recovery

This is currently the most notable and valuable method of utilization of CO2 [13]. A large percentage of CO2 used in enhanced oil recovery is derived from the burning of fossil fuels.

Enhanced oil recovery also provides the advantage of storing carbon dioxide in the depleted hydrocarbon reservoir after the oil and gas have been extracted. As the search for hydrocarbons becomes more complex and intensive, we are bound to see further development in the use of CO2 for enhanced oil recovery.

Challenges of Enhanced Oil Recovery by CO2 Injection

However, there are a number of challenges which are associated with the use of CO2 for enhanced oil recovery.

The most notable challenge is the fact that the extraction of oil and gas means that there would be more production of CO2, during the recovery, processing and usage of these hydrocarbons. There is therefore the serious question of whether the CO2 injection process leads to net negative (reduced) emissions at all.

Also, the amount of CO2 which is needed for EOR is rather negligible compared to the amount of CO2 which we need to remove from the atmosphere. In most projects involving EOR by CO2 injection, a limit of 60,000,000 tons of CO2 is used [6].

In spite of these problems, CO2 injection remains a prominent practice on the oil and gas sector. Most major oil and gas companies actively deploy this method in their exploration projects, in various parts of the world.

2). Fuel Production

Carbon dioxide can be converted into liquid fuels such as methanol and dimethyl-ether [21]. This is potentially beneficial since fossil fuels have high energy density and are relatively efficient.

However, the process of conversion will require energy. So far, efforts to utilize CO2 for liquid fuel production have not been commercially successful, although renewable energy options have been considered.

The combination of CO2 and hydrogen to produce syngas and methanol, and has potentials of success in the economic market. This is because the fuels produced can be used in transport and other utilities.

3). Chemical Production

Carbon dioxide can be used in the chemical industry as feedstock for chemical production processes.

This is a potentially beneficial option, especially as it will eliminate the need for oil as a feedstock. This implies some positive outcomes for the environment. Also, it will be more economically feasible than renewable energy sources which are relatively expensive.

CO2 has already been used in the bulk production of some important chemicals. Examples of these include salicylic acid (used in manufacturing pharmaceuticals); Plastic Polycarbonates; Dimethyl Carbonate; and Urea (used in manufacturing nitrogenous fertilizers).

Additionally, it has been used as a solvent in other important chemical processes.

The reduction of CO2 through catalyzed chemical reactions, to produce these chemical products like urea and polymers, is capable of using up to 600 million tons of CO2 annually, by the year 2050.

4). Use of CO2 in Building and Construction

It is known that the cement production sector is an important emitter of carbon dioxide globally.

Speculations have suggested that carbonate minerals cam be used in place of most synthetic building materials.

This approach will have the advantage of reducing CO2 emissions significantly for the construction industry, which currently emits up to 38% of global carbon [29].

Captured CO2 can also be directly incorporated into concrete, in a process which we may refer to as ‘curing’. This will serve as means of storage of the CO2, while increasing the durability of the structures constructed [23]. The approach can potentially store up to 140 million tons of CO2, by the year 2050.

5). Microalgae

Microalgae can be used efficiently, to fix CO2, through the process of carbon sequestration.

This biomass is subsequently processed in order to develop some important products like chemicals and biofuels. There has been much research of recent, with respect to this method of carbon dioxide utilization.

Safety of the Carbon Capture Process

In the decades of its use, carbon capture technology has been found to be fairly safe [17]. This is with regards to both small and large scale carbon capture and storage (CCS) projects.

Potentials of Carbon Capture Technology

Caron Capture and Storage has very good potentials as an industrial technology. It is capable of addressing global warming and climate change, by reducing atmospheric emissions of CO2 from major industrial outlets.

By this approach, carbon capture is capable of helping in the efforts to achieve negative emissions, as part of the sustainable development initiative. In line with the Paris Agreement of restricting global rise in temperature to below 2°C, carbon capture technology will require improvements in efficiency, effectiveness and scale of operation.

Effectiveness and Efficiency: Why is Carbon Capture Technology Important?

The obvious point of importance of carbon capture technology lies in its usefulness to our environment. In terms of its effectiveness, carbon capture technology is capable of removing up to 90 percent of all CO2 released from fossil fuel-driven facilities [3].

On a global scale, carbon capture is capable of reducing about 14 percent of greenhouse emissions by the year 2050. It is therefore viewed as the most feasible de-carbonization method.

The power-generation sector stands to benefit from carbon capture technology. This is because CO2 can be used to efficiently drive steam turbines due to their ability to be compressed to form a supercritical fluid at high pressure. Liquid fuel that is produced using CO2 can also serve as a source of energy.

Geothermal energy can be derived by the circulation of CO2 which has been stored in underground geologic formations. This is a renewable form of energy, and is therefore favorable to the environment.

Job creation is yet another inevitable potential of carbon capture technology. With its further development, more skilled labor will be required to effectively manage CCS facilities and processes.

Associated Risks of Carbon Capture and Storage Technology

While we have seen earlier that the carbon capture process is generally safe, there are a few potential risks involved.

The most important risk associated with carbon capture is the issue of potential leakage.

However, the degree of impact caused by CO2 leakage depends significantly on the nature and scale of the leakage itself. In general, the potential hazard increases with increase in the scale of leakage.

Where the leakage is slow and intermittent, the degree of impact is also relatively low. Large and explosive leakages pose the greatest threat, as they can lead to asphyxiation and death. Such leaks are likely to result from sudden damage to reservoirs or pipeline structures.

An example of a significant cases of CO2 leakage is the release of the gas in large volumes from Lake Nyos, Cameroon, in 1986, resulting in the deaths of 1,700 regional dwellers [2]. Environmental acidification occurred as a result of CO2 leakage from an underground reservoir in California, affection plants, soil and water.

The risk of hazards of CO2 leakage can be reduced significantly, by choosing well confined storage sites. Such sites would include non-heterogeneous geologic formations and subsea geologic reservoirs.

Global Application of Carbon Capture Technology

Up to 40 million tons of CO2 released from industrial plants around the world, are captured on a yearly basis. Tze United States plats host to about 10 major carbon capture facilities, which constitutes about one-fifth the total number of large-scale CCS plants worldwide.

These facilities are individually able to capture no less than 800,000 tons of CO2 yearly. Also, they occur in Europe, the Middle-East, the Americas, and the Asia-Pacific.

Although the UK commenced operations in its first large-scale carbon capture plant in 1996, the US has actively utilized carbon capture technology since 1972, with am estimated capture and storage of at least 190 million tons of CO2 within the region, so far.

The Middle East and North Africa region (MENA), began active operations in its first large-scale, commercial CCUS facility, which is located in Abu Dhabi. This project is aimed at achieving the capture and storage at least 800,000 tons of CO2 annually. It basically extracts CO2 from the flue gas of steel manufacturing plants, storing it by injection into underground depleted oil and gas reservoirs.

Carbon Capture Technology and Climate Change

As we have highlighted in several other sections of this article, carbon capture stands as a potentially viable option for addressing climate change and global warming.

According to the Intergovernmental Panel on Climate Change (IPCC), achieving the objective of the Paris Agreement which entails reducing global temperature increase to about 1.5°C, atmospheric carbon concentrations must be reduced. This need, shows that carbon capture technology is very important to climate change.

Difficulties and Challenges of Carbon Capture and Storage

1). Economic Challenges

The carbon capture process is relatively expensive. This is as a result of the cost of equipment, construction and deployment of carbon capture facilities, as well as the cost of energy required to drive the entire process of isolating, compressing and transporting CO2.

As matter of fact, the cost of deployment of carbon capture technology is a very significant challenge which reduces the feasibility of large scale projects.

The process of capturing CO2 often reduces the efficiency of CCS facilities, and may increase the demand for water as an ingredient in the process, both cases of which imply additional costs.

These issues create risks of significant financial losses with minimal potential returns. It is therefore essential, as part of measures to undertake in the development of CCS, to optimize the cost of equipment and operations. This would help enhance the practical use of the technology by encouraging more investors to support CCS projects.

2). Transportation Challenges

The transport of captured CO2 also poses a few challenges.

One of these is the fact that transport of CO2 is relatively costly, as there is high energy demand for compression and pumping of the gas.

Additionally, the pipeline facilities required for transporting CO2 are expensive. This is because they are specifically designed to suit the conditions of the gas captured from a particular source.

Another challenge is the risk of leakage during transport. The CO2 may be highly acidic, or may contain impurities which are capable of corroding and damaging the pipelines. There is also a significant level of difficulty involved in linking the transport facility from the source directly to the point of storage.

3). Complexity

Carbon capture technology presents several different options in terms of the methods by which it cam be carried out.

This introduces a great level of complexity, as each individual option is accompanied by its unique cost and requirements.

Complexities in the choice of method, and in the process of carbon capture itself, can be reduced through further research and development to determine and select best approaches.

4). Environmental Effects

The environmental effects of carbon capture are mostly related to the risk pf leakage of captured CO2 [30].

As we have earlier seen, such leakage can result in various forms of negative impacts on the quality of air, soil and water, by displacing oxygen and causing acidification.

5). Challenges of Storage

In general, geologic storage sites for captured CO2, are not a scarce commodity.

However, there are concerns regarding the suitability of most of the available geologic formations (and other potential storage sites) for effective carbon capture and retention.

This is because several of these sites are affected by some unfavorable characteristics like heterogeneity, excessive porosity, as well as physical and chemical instability.

Such characteristics reduce the potential to store carbon on a long-term basis, without any serious degree of leakage.

6). Biased Public Opinion

In the early stages of its introduction, carbon capture technology received much support from the public. Obviously, we can understand that this support was driven by the prospect that CCS technology could motivate global warming and climate change.

However, there appear to have been slight changes in public opinion over the years. One reason for this is the fact that carbon capture technology suggests that fossil fuels will continue to be in use.

Given the fact that much effort is being made to develop renewable energy technologies, the interest of the public (which includes potential investors and policy-makers) is more inclined toward renewables.

Another reason is the obvious fact that carbon capture technology has had a relatively slow pace of development. As a result, CCS applications have not been nearly as effective as they proposed to be at the onset. In addition to this, there is very little evidence by which to debate the viability and reliability of carbon capture technology.

Policies and Regulations related to Carbon Capture and Storage Technology

The goal of the Paris Agreement is basically to minimize the increase in average global temperature. Basically, this entails keeping it below 1.5°C. The same objective is pursued by the Sustainable Development Goals, developed by the United Nations.

Several other policies have been implemented which support the utilization of carbon capture technology. In the United States, tax credits exist for carbon sequestration, at both the state and national levels [18].

A report by the Intergovernmental Panel on Climate Change, on Carbon Dioxide Capture and Storage, suggests that policies can be used to enhance the development of CCS technology. These policies must encourage more demand, less cost, as well as more research and development to optimize the use of the technology.

Other policies like the Enhancing Fossil Fuel Energy Carbon Technology Act, and the Launching Energy Advancement and Development through Innovations for Natural Gas Act, are also capable of influencing positive developments in carbon capture technology over time.

Other Terms of relevance with Respect to Carbon Capture

– Standing Biomass

Marine biodiversity such as microalgae which we have already discussed, can be used to absorb CO2.

However, in the context of ‘standing biomass’, the algae (or other organisms used), are not further utilized in the production of other materials. Rather, the algae will remain on the seafloor and would be consumed by other marine organisms in the course of natural nutrient cycling.

– Bioenergy with Carbon Capture and Storage (BECCS)

Bioenergy with Carbon Capture and Storage (BECCS) involves the capture of CO2 through the planting of trees.

This method aids in the production of electricity, with minimal CO2 atmospheric emission. It is projected that the method can lead to the utilization and storage of up to 5 billion tons of CO2 annually, by the year 2050.

– Carbon Sequestration in Soil

This is the natural process by which carbon is stored in the soil.

In addition to serving as a means by which CO2 can be stored, soil carbon sequestration is capable of improving the fertility of soil and therefore the ability of the soil to support agricultural productivity.

– Biochar

Biochar refers to plant biomass which has been subjected to pyrolysis, by heating intensely under low-oxygen conditions [20]. It is a valuable material in agriculture, as it enhances soil productivity and crop yield.

– Carbonate Dissolution

The dissolution of carbonates to produce bicarbonates is means by which CO2 can be absorbed and utilized, especially in seawater. However, there are no known methods by which this reaction can be simulated in an economical manner.

Criteria which Determine the Quality of Carbon Capture Technology

1). Scale of Operation

The value and relevance of carbon capture technology is strongly linked to the scale at which it is practiced.

Large-scale operations of carbon capture technological plants, is obviously essential if we are to make any significant progress our efforts to reduce atmospheric concentrations of CO2 and mitigate the associated challenges.

2). Degree of Permanence

Basically, the quality of carbon capture can be judged based on how effectively it can rive carbon dioxide from the atmosphere, for the long-term.

This implies that the most successful and valuable carbon capture technologies are those which will be able to permanently displace or remove CO2 atmospheric emissions.

3). Source of Energy

Because of the energy-intensive nature of Carbon capture, storage and utilization, the ability for incorporate renewable energy technology into the process will increase the overall effectiveness and quality.

4). Scope

‘Scope,’ here, refers to how broad the effectiveness of de-carbonization technology can be.

An effective way to increase the value of carbon capture technology is to broaden the practical context and conditions in which it can be applied.

Critical Factors and Conditions for Carbon Capture and Storage

The success, growth and development of carbon capture technology depends on a number of important factors.

These include support from political entities, investors, and the general public.

In order for investors to support CCS technology, it is necessary for the economic potential and viability of the process, to be improved. This will help provide the assurance of return on investment, for such individuals.

To achieve this, consistent political support is also necessary, as this will address the challenges of public resistance and stiff government policies. Carbon capture technology must be developed such that there will be market stability, revenue generation, and minimal technical risk.

A well-trained, skilled workforce is essential to ensure that operations in CCS plants are reliable and efficient. This means that research and development are important, so as to determine and develop the best approaches.

In order for CCS technology to gain public support, it is needful for carbon capture projects to be carried out with proper decision-making, while ensuring that stakeholder engagement is practiced throughout the course of such projects. Of course, the public is a fundamental stakeholder, alongside investors and government agencies.

CSS projects should be carried out in such a manner as will be beneficial to the local economy and will not involve environmental degradation.

As has already been mentioned, political entities constitute an important stakeholder with respect to the growth and development of carbon capture technology. This is because of their ability to develop policies and influence public opinion on the importance of CCS.

What is Needed to Improve and Optimize Carbon Capture and Storage Technology

In order to optimize carbon capture and storage technology in terms of its effectiveness and profitability, he following are required;

1). Sufficient concentration of CO2 in flue gas is important. Gas streams with relatively high CO2 concentration, make the process of carbon capture to be more worthwhile and effective.

2). Geologic storage sites must be within fairly close range to the site of carbon capture. This will reduce the cost and risk involved in transporting the CO2 after it has been isolated from flue gas streams.

Also, adequate geological data is essential to identify the best storage locations. A distance of 500km or less would be helpful.

3). The overall process of capture and storage is required to be financially rewarding.

4). Government engagement and support for CSS, with an understanding of is importance to the society.

5). The regulation and management of CO2 storage must be transparent, sustainable and reliable on a long-term basis

Some Important Carbon Capture and Storage Companies

-

Global Thermostat

Established in the year 2010, in New York, U.S.A, Global Thermostat operates in both direct atmospheric capture of carbon, and isolation of carbon from industrial gas streams.

The captured gas is subsequently sold to different industries for manufacturing and catalytic purposes.

Global Thermostat makes use of amine-based adsorbents within a ceramic, monolithic framework. In the process of carbon capture, the adsorbents soak up, and absorb carbon from the atmosphere of from flue gas streams.

The CO2 which has been captured is isolated from the monoliths by the use of steam within a temperature range of 85-100°C. Subsequently, the isolated carbon is transported to the points of need.

To ensure that the process is relatively sustainable, Global Thermostat uses steam which is produced from process heat during carbon capture. This helps to optimize the overall cost of operation.

Also, in order to reduce the risk, complexity and cost of transport, the company ensures that its facilities are situated within close distance of industries and power generation plants in need of their services.

-

Carbfix

With its base located in Reykjavik, Iceland, Carbfix has been actively involved in the capture of carbon from the Hellisheiði Power Plant since the year 2014. The company aims to achieve the storage of 1 billion metric tons of CO2 within a short time frame; aa part of measures to tackle climate change.

The dominant approach used by Carbfix, is carbon capture from flue gas streams from the industrial source point. The captured carbon is subsequently dissolved in water and stored in underground geologic formations, into which it is injected in its dissolved state.

Often, the carbon is injected into formations composed of basalt or other suitable reactive rocks, in order to facilitate chemical reactions that lead to the formation of stable carbonate minerals.

The uniqueness of the approach to carbon dioxide storage which is used by Carbfix, is the fact that it provides an avenue by which carbon can be stored in a permanent and relatively safe manner.

Although it was earlier believed that the formation of carbonate minerals by reaction between carbonic acid and rock materials, takes a long duration of time, recent observations have shown that it can be achieved within few years [22].

-

Climeworks

Based in Zurich, Switzerland, Climeworks is a carbon capture company which commenced developing its technology in 2007, before being fully established in 2009.

It is the one of largest carbon capture companies globally, and operates mainly by direct atmospheric capture of CO2.

The company uses a combination of direct atmospheric capture, and an adapted method of underground storage introduced by Carbfix (which we have earlier discussed).

Modular CO2 collectors are the main equipment used to capture carbon dioxide directly from the atmosphere. These collectors are used in combination to produce elaborate carbon capture machines that are suited to purpose.

The carbon capture process used by Climeworks, occurs in two stages. The first of these. involves the pulling-in of air into the modular collector. This is done by a fan-driven system, which is built within the collector itself.

In the second stage, the modular collector closes and the temperature is increased to between 80-100°C. This helps to isolate carbon from the collected air, which is then transported for storage or re-use.

Climeworks is unique for its operations in carbon capture directly from the atmosphere. To achieve energy efficiency, the company employs renewable technology to power its modular collector system.

-

Net Power

With its headquarters in Durham, in North Carolina, United States, Net Power commenced the development of its technology in 2008. The objective of the company and its technological approach, is basically to develop power generation systems that operate at low cost and produce little to no carbon emissions.

This objective has led to the development of the Allam-Fetvedt power cycle, which was further enhanced to produce NET Power technology in 2010. The NET Power technology aims to produce sufficient electricity using natural gas-driven power plants running on the Allam-Fetvedt Cycle, by the year 2050.

Net Power generates electricity simply by the combustion of natural gas in pure oxygen. This is very similar to the oxy-fuel carbon capture method. It ensures that nitrogen oxide is not produced.

The carbon produced (alongside hydrogen) from this process, is recycled by heating, cooling and compressing it. This results in emission-free electricity at relatively low cost. Excess carbon which cannot be recycled, is then sold to industries of need.

-

Quest Carbon Capture and Storage by Shell

Shell oil and gas company, runs the Quest carbon capture plant, in Alberta, Canada, where they also have their Scotford Upgrader power plant.

The facility is used by Shell, to capture and remove carbon which is produced at the power plant in the process of conversion of bitumen to liquid crude oil. After its capture, the carbon is transported away in pipelines and injected for storage, into porous geologic formations at an average depth of 2km.

The technology used for carbon capture at Quest is simple amine absorption. After the CO2 is separated from the amine absorbent, it is usually compressed, which converts it to liquid state, before it is transported, over a distance of about 65km, to the storage site.

-

CO2 Solutions by SAIPEM

Established in the year 1997, CO2 Solutions by SAIPEM has its base in Quebec, Canada. The company operates using a unique carbon capture technology designed to function similar to the human lung.

Here, carbon capture is basically catalyzed using an industrial form of carbonic anhydrase (CA), the natural enzyme that helps in the gaseous exchange process on the human body. The method is capable of capturing about 99.95% of carbon in flue gas. This captured carbon is usually sold to industries that require it.

The primary sources which this company focuses on, include plants, installations and facilities that produce carbon as a waste material.

-

Carbon Engineering

Established in Calgary, Canada, in 2008, Carbon Engineering completed its pioneer plant in Squamish, in 2015. The purpose of this plant was mainly to capture carbon from the atmosphere, directly, and utilize or store it.

The company has worked with several other establishments in and beyond the US, for the purpose of carbon sequestration and clean fuel production.

The technology used includes a modular collector, or ‘contactor’ with a built-in fan system that helps to pull air from the atmosphere. The collected air is brought into contact with potassium hydroxide solution, which isolates carbon, while the remaining air is released.

-

Mirreco

Mirreco is an Australian company which specializes in developing Carbon Asset Storage Technology, products (CAST).

The carbonic raw material used for these products may also be called ‘industrial hemp,’ and the products themselves include textiles, construction materials, biodegradable plastics and biofuel.

Conclusion

As we have seen in this article, carbon capture is a fairly complex and very important technology.

In addition to the limitations and challenges involved in its development, it is obvious that other technologies and practices are needed if we are to successfully tackle carbon emissions, global warning and climate change.

There have been several modifications to the known methods of carbon capture. Most of these innovative efforts have not been very successful, however, we can expect to see some positive developments in the near future.

References

1). Al-Abbas, H.; and Naser, J. (2012). “Oxy–Fuel Combustion in the Lab–Scale and Large–Scale Fuel– Fired Furnaces for Thermal Power Generations.” Available at: https://www.intechopen.com/chapters/44234. (Accessed 9 November 2021).

2). Bubnoff, V. A. (2005). “Deadly lakes may explode again.” Available at: https://www.nature.com/articles/news050926-4. (Accessed 10 November 2021).

3). C2ES (2021). “Carbon Capture.” Available at: https://www.c2es.org/content/carbon-capture/. (Accessed 10 November 2021).

4). Cho, R. (2018). “Why Thawing Permafrost Matters.” Available at: https://news.climate.columbia.edu/2018/01/11/thawing-permafrost-matters/. (Accessed 10 November 2021).

5). Clifford, C. (2018). “Carbon capture technology has been around for decades — here’s why it hasn’t taken off.” Available at: https://www.cnbc.com/2021/01/31/carbon-capture-technology.html. (Accessed 10 November 2021).

6). El-hoshoudy, N.; and Desouky, S. (2018). “CO2 Miscible Flooding for Enhanced Oil Recovery.” DOI: 10.5772/intechopen.79082. Available at: https://www.intechopen.com. (Accessed 10 November 2021).

7). Energy.gov (2021). “Pre-Combustion Carbon Capture Research.” Available at: https://www.energy.gov/fecm/science-innovation/carbon-capture-and-storage-research/carbon-capture-rd/pre-combustion-carbon. (Accessed 9 November 2021).

8). Energy.gov (2021). “Carbon Storage R&D.” Available at: https://www.energy.gov/fecm/science-innovation/carbon-capture-and-storage-research/carbon-storage-rd. (Accessed 10 November 2021).

9). IEA (2021). “Why carbon capture technologies are important.” Available at: https://www.iea.org/reports/the-role-of-ccus-in-low-carbon-power-systems/why-carbon-capture-technologies-are-important. (Accessed 9 November 2021).

10). Greenfacts (2021). “The main options for transport of captured CO2 include road (in tankers), rail, sea (in ships and shuttle tanks), and pipelines.” Available at: https://www.greenfacts.org/en/co2-capture-storage/l-3/4-transport-carbon-dioxide.htm. (Accessed 9 November 2021).

11). Leung, D. Y. C.; Caramanna, M.; Maroto-Valerb, M. (2014). “An overview of current status of carbon dioxide capture and storage technologies.” Renewable and Sustainable Energy Reviews, vol. 39. Available at: https://doi.org/10.1016/j.rser.2014.07.093. (Accessed 9 November 2021).

12). lse.ac.uk (2018). “What is carbon capture and storage and what role can it play in tackling climate change?.” Available at: https://www.lse.ac.uk/granthaminstitute/explainers/what-is-carbon-capture-and-storage-and-what-role-can-it-play-in-tackling-climate-change/. (Accessed 9 November 2021).

13). Lopez, N., V.; and Moskal, E., (2019). “Potential of CO2-EOR for Near-Term Decarbonization.” Front. Clim. Available at: https://doi.org/10.3389/fclim.2019.00005. (Accessed 10 November 2021).

14). McGlade, C. (2019). “Can CO2-EOR really provide carbon-negative oil?.” Available at: https://www.iea.org/commentaries/can-co2-eor-really-provide-carbon-negative-oil. (Accessed 9 November 2021).

15). Mohitpour, M.; Sortland, K. (2011). Pipeline Transportation. Kirk‐Othmer Encyclopedia of Chemical Technology. Available at: https://doi.org/10.1002/0471238961.1609160523080112.a01.pub2. (Accessed 9 November 2021).

16). National Geographic (2011). “Permafrost.” Available at: https://www.nationalgeographic.org/encyclopedia/permafrost/. (Accessed 10 November 2021).

17). National Grid (2021). “What is Carbon Capture and Storage?” Available at: https://www.nationalgrid.com/stories/energy-explained/what-is-ccs-how-does-it-work. (Accessed 10 November 2021).

18). NCSL (2021). “State Forest Carbon Incentives and Policies.” Avaliable at: https://www.ncsl.org/research/environment-and-natural-resources/state-forest-carbon-incentives-and-policies. (Accessed 10 November 2021).

19). NETL (2021). “WHAT IS CARBON CAPTURE AND STORAGE?” Available at: https://netl.doe.gov/coal/carbon-storage/faqs/carbon-storage-faqs. (Accessed 10 November 2021).

20). Oelbermann M., Berruti F., and Lévesque V. (2020). “Biochar and its Use in Soil: Lessons from Temperate Agriculture.” Available at: https://lupinepublishers.com/environmental-soil-science-journal/fulltext/biochar-and-its-use-in-soil-lessons-from-temperate-agriculture.ID.000211. (Accessed 10 November 2021).

21). Qinjie, J. G.; Wen, Z. R.; Fang, C.; Guo, L.; Xu, H.; & Sun, J. (2017). “Directly converting CO2 into a gasoline fuel.” Nature Communications. Available at: https://www.nature.com/articles/ncomms15174. (Accessed 10 November 2021).

22). D. Rathnaweera, P. G. Ranjith & M. S. A. Perera (2016). “Experimental investigation of geochemical and mineralogical effects of CO2 sequestration on flow characteristics of reservoir rock in deep saline aquifers.” Scientific Reports. Available at: https://www.nature.com/articles/srep19362. (Accessed 10 November 2021).

23). Ravikumar, D.; Zhang, D.; Keoleian, G; Miller, S; Sick, V.; & Li, V. (2021). Carbon dioxide utilization in concrete curing or mixing might not produce a net climate benefit. Nature Communications. Available at: https://www.nature.com/articles/s41467-021-21148-w. (Accessed 10 November 2021).

24). Selin, N., E.; and Rafferty, J. P. (2011). “carbon sequestration: Additional Information.” Available at: https://www.britannica.com/technology/carbon-sequestration. (Accessed 9 November 2021).

25). Scied.ucar.edu (2021). “Carbon Capture and Storage.” Available at: https://scied.ucar.edu/learning-zone/climate-solutions/carbon-capture-storage. (Accessed 10 November 2021).

26). Singh, J.; and Dhar, W. D. (2019). Overview of Carbon Capture Technology: Microalgal Biorefinery Concept and State-of-the-Art. Front. Mar. Sci. Available at: https://doi.org/10.3389/fmars.2019.00029. (Accessed 9 November).

27). Songolzadeh, M.; Soleimani, M.; Takht R., Songolzadeh, R. (2014). “Carbon Dioxide Separation from Flue Gases: A Technological Review Emphasizing Reduction in Greenhouse Gas Emissions”, The Scientific World Journal. Available at: https://doi.org/10.1155/2014/828131. (Accessed 9 November 2021).

28). Teir, S.; Tsupari, E.; Koljonen T.; Pikkarainen, T. (2009). Carbon capture and storage (CCS). Available at: https://www.researchgate.net/publication/288200424_Carbon_capture_and_storage_CCS. (Accessed 9 November 2021).

29). UNEP (2020). “Building sector emissions hit record high, but low-carbon pandemic recovery can help transform sector – UN report.” Available at: https://www.unep.org/news-and-stories/press-release/building-sector-emissions-hit-record-high-low-carbon-pandemic. (Accessed 10 November 2021).

30). Vinca, A.; Emmerling, J. (2018). “Massimo Tavoni Bearing the Cost of Stored Carbon Leakage.” Front. Energy Res. Available at: https://doi.org/10.3389/fenrg.2018.00040. (Accessed 10 November 2021).

31). Wang, X.; and Song, C. (2020). “Carbon Capture From Flue Gas and the Atmosphere: A Perspective. Front. Energy Res. Available at: https://doi.org/10.3389/fenrg.2020.560849. (Accessed 9 November 2021).

32). Wikipedia (2021). “Flue Gas.” Available at: https://en.m.wikipedia.org/wiki/Flue_gas. (Accessed 9 November 2021).