Automation Definition, Types, Applications, Examples, Pros/Cons

Automation is a system of operation that uses artificial intelligence to program functions, such that they proceed without active human supervision or facilitation. This article discusses automation definition, types, application, examples, advantages and disadvantages, as outlined below;

-Automation Definition: 3 Ways to Define Automation

-Definition of Some Terms in Automation

Automation Definition: 3 Ways to Define Automation

Automation is the use of artificial intelligence tools and techniques to enable functions to proceed with minimal human intervention [2].

The above describes automation in computer science. Within the same context, it is possible to identify links between automation and other concepts like machine learning and deep learning.

Aside computer science, there is also a concept of automation in business. Below is an alternative automation definition that highlights this perspective;

Automation is the act and process of equipping human institutions with technologies and/or methods by which repetitive or difficult tasks can be handled without much need for supervision or human labor.

Within the context of business and socioeconomy, automation is very important. It constitutes an aspect of sustainable development schemes, in the form of green economic practices, sustainable manufacturing, and circular economic methods like recycling [4].

An alternative automation definition can be provided which highlights the concept in terms of existing types, as shown below;

Automation refers to the function of digital data-driven algorithms that are employed to mimic human autonomous capabilities in artificial systems, and which may occur in any of various types including; fixed, flexible, integrated and programmable automation [3].

Definition of Some Terms in Automation

Some terms in automation that should be clarified include; automation software, program, system, and technology.

1). Automation Software

Automation software refers to applications that are designed to implement or facilitate a particular functionality in automation systems.

They are often designed from automation programs or algorithms, and are tailored to serve a specific purpose or range of functions.

2). Automation Program

Automation programs are the algorithms or commands that make up automation software applications.

They can also be described as detailed instructions that are used to guide the operations of automation systems.

3). Automation System

An automation system is a definite unit that performs automated functions.

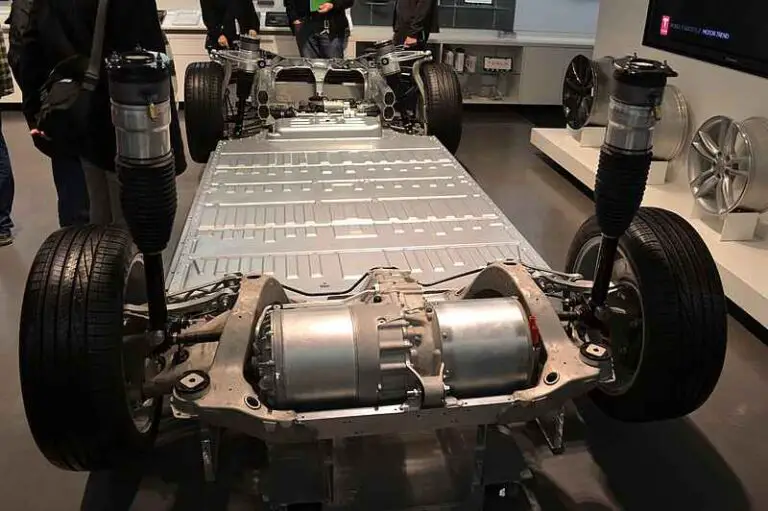

Automation systems are common in robotics engineering, and serve a broad range of purposes from energy management to autonomous driving in electric cars.

4). Automation Technology

Automation technology refers to the combination of automation software, programs and systems to produce a definite, functional concept.

Therefore, the term automation technology can be used to refer to any of its components in various scenarios.

Types of Automation

Types of automation are; fixed, flexible, programmable and integrated automation; each of which is discussed below;

1). Fixed Automation

Also referred to as 'hard' or 'rigid' automation, fixed automation is a type of automation that is based on algorithms and neural networks that have been developed to operation on a unidirectional basis, so that the automation process adopts a singular process or pathway, as well as a singular function and/or product.

Fixed automation is usually applied in (and is recommendable for) systems and functions that are relatively simple and require a singular process and outcome.

2). Flexible Automation

Flexible automation is a type of automation that is highly adaptive and capable of switching between variable tasks instantaneously [1].

It is usually based on elaborate programs and neural networks that do not need modification in-between functions.

3). Programmable Automation

Programmable automation is a signal-based type of automation that is designed to operate sequentially in terms of the performance of tasks.

Unlike flexible automation, programmable automation is not necessarily based on adaptive or elaborate neural networks. Rather, it is based on relatively simple algorithms that share a bi-directional, responsive relationship with data, so that tasks can be initiated based on signals from available datasets.

Programmable automation is best used with systems and scenarios involving tasks that are sequential or occur in batches, such as in manufacturing.

4). Integrated Automation

Integrated automation exhibits advanced capabilities in terms of autonomy and efficiency, as a result of combined characteristics from various types of automation.

It is highly dependent on effective data classification and specification of parameters, and is useful for systems whose operations are multidimensional and complex.

Applications of Automation

Applications of automation are;

1). Sustainable Manufacturing

2). Quality Control

3). Autonomous Transport

4). Environmental Remediation, Assessment, Monitoring and Management

5). Arc Welding

6). Sustainable Irrigation and other automated Sustainable Agricultural Practices

7). Security System Operations

8). Energy Management

Examples of Automation

Examples of automation are;

1). Natural Language Processing in Search Engines and Databases

2). Self-driving in Vehicles

3). Robotic Fuel Dispensation

4). Automated Security Systems and Operations

5). Interactive AI and Virtual Assistance

Advantages of Automation

Advantages of automation are;

1). Facilitation of economic sustainability

2). Increase in productivity

3). Energy efficiency improvement for most operations

4). Resource conservation

5). Improvement of work safety

6). Fortification of security systems

7). High quality output

Disadvantages of Automation

Disadvantages of automation are;

1). High capital investment

2). Human unemployment

3). Technical skill and knowledge requirement

4). Relatively-low versatility and flexibility

5). High electricity demand may have negative environmental impact

Conclusion

Automation refers to tools, techniques and systems that help enable data-based, mechanical, and evaluative processes to occur without human intervention.

Some terms in automation include;

1. Automation Software

2. Automation Program

3. Automation System

4. Automation Technology

Types of automation are;

1. Fixed Automation

2. Flexible Automation

3. Programmable Automation

4. Integrated Automation

Applications of automation are; sustainable manufacturing, quality control, autonomous transport, environmental management, arc welding, sustainable agriculture, security operations, and energy management.

Examples of automation are; natural language processing in search engines, vehicular self-driving, robotic fuel dispensation, automated security, and interactive AI.

Advantages of automation are; facilitation of economic sustainability, increase in productivity, energy efficiency, resource conservation, work safety, security fortification, and high-quality output.

Disadvantages of automation are; high capital, human-labor displacement, technical skill/knowledge requirement, potential negative effect on ecosystem, relatively-low versatility and flexibility.

References

1). Linsinger, M.; Sinnemann, M.; Kutschinski, J.; Kuhlenkötter, B. (2019). "Situational task change of lightweight robots in hybrid assembly systems." Procedia CIRP 81:81-86. Available at: https://doi.org/10.1016/j.procir.2019.03.015. (Accessed 6 January 2023).

2). Marshall, I. J.; Wallace, B. C. (2019). "Toward systematic review automation: a practical guide to using machine learning tools in research synthesis." Systematic Reviews 8(1). Available at: https://doi.org/10.1186/s13643-019-1074-9. (Accessed 6 January 2023).

3). Pil, F.; MacDuffie, J. P. (1997). "From Fixed to Flexible: Automation and Work Organization Trends from the International Assembly Plant Study." Available at: https://doi.org/10.1007/978-3-642-60374-7_17. (Accessed 6 January 2023).

4). Turner, C.; Oyekan, J.; Garn, W.; Duggan, C.; Abdou, K. (2022). "Industry 5.0 and the Circular Economy: Utilizing LCA with Intelligent Products." Sustainability 2022, 14, 14847. Available at: https://doi.org/10.3390/su142214847. (Accessed 6 January 2023).