7 Types of Steam Turbines Explained

Types of steam turbines are; impulse, reaction, back-pressure, extraction, condensing, radial-flow and axial-flow turbines. They are classified based on design and mode of operation.

This article discusses the types of steam turbines, as follows;

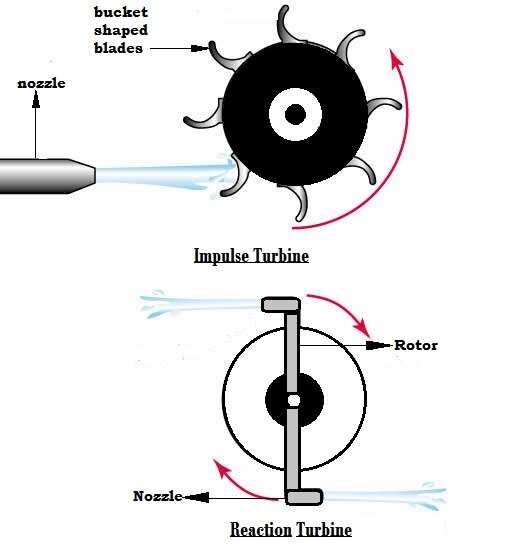

1). Impulse Turbine (as one of the Types of Steam Turbines)

Impulse steam turbine is a simple type of steam turbine that is designed to convert the force of a jet-stream of pressurized steam into mechanical energy of rotation.

The principle of impulse turbine is Newton's principle of inertia; which is part of the Second Law and is based on the proportionality of changing impulse, and momentum [5]. This principle is utilized so that the acceleration of the turbine blades under the force of pressurized steam generates impulsive mechanical motion.

The formula below shows the relationship between impulse, force, momentum, acceleration and time;

I = F × t = m × a × t= m (v-u) = M --- (1)

Where;

I= Impulse (Ns)

F= Force (N)

t= Time (s)

a= Acceleration (m/s^2)

m= Mass (kg)

v= Final Velocity (m/s)

u= Initial Velocity (m/s)

M= Momentum (kgm/s)

Steam turbines often have some typical impulse-type characteristics, which may be combined with reaction-type characteristics to achieve optimal energy efficiency and performance.

The impulse type turbine is equipped with buckets; which are hollow crevices that maximize the impulsive force of steam that strikes the blades. Condensed water often flows out from the bottom of the casing of the turbine.

2). Reaction Turbine

Reaction steam turbine is a type of steam turbine that produces mechanical energy using the impulsive force and velocity of a stream of steam.

The difference between impulse and reaction steam turbines is that the impulse turbine uses only impulsive force for its rotation, while reaction turbine is more efficient and uses both impulsive force and fluid velocity for its rotation.

In a reaction turbine, there is a higher rate of energy conservation than in impulse turbine, because the reaction turbine is designed with rows of both fixed and moving blades which ensure that steam pressure is captured along the entire length of the turbine shaft; while the impulse turbine depends solely on its fluid-capturing buckets to harness the pressure of steam.

Types of reaction turbines are; Kaplan, Bulb, Gravity, Propeller, Tube, Francis and Straflo turbines.

An example of reaction steam turbine is the Parsons Steam Turbine, which invented by Charles A. Parsons in 1884 for use in marine vessels and other machinery [4].

Steam turbines are often designed to include impulse and reaction stages [6]; where the impulse stage is specialized for high-pressure operations and the reaction stage is suited for low-pressure operations.

Types of Steam Turbines: Impulse and Reaction Turbines (Credit: Ashumech 2014 .CC BY-SA 4.0.)

3). Back Pressure Turbine (as one of the Types of Steam Turbines)

Back pressure steam turbine (also called non-condensing steam turbine) is a type of steam turbine that operates by expanding steam-streams using valves, to reduce the pressure of the steam before converting this pressure (and thermal energy) to mechanical energy.

The back pressure turbine is used with industrial equipment that are designed for low-pressure operation. In steam boilers, back pressure is used to describe all conditions where the pressure of steam supplied to a target destination by the boiler, is lower than the pressure of steam in the boiler.

The difference between back pressure and condensing turbines is that back pressure turbine minimizes energy waste by preventing rapid steam-condensation, in order for the thermal energy of steam to be utilized for other applications.

Back pressure turbines control steam pressure using valves, while in condensing turbines, pressure control is achieved mainly by condensation.

The use of back pressure turbine is most suitable where there is need to utilize process-steam at more than one pressure. A specialized sub-type called the extraction back pressure turbine is often used to achieve this [2].

Facilities that employ back pressure steam turbines include; small-scale mechanical drives, power plants and steam generators.

4). Extraction Turbine

Extraction steam turbine is a type of steam turbine that is specially equipped to allow for the removal or 'extraction' of steam at various stages of a thermal industrial process.

The word extraction in steam turbines simply means the isolation of any given volume or body of fluid, from a larger body. Steam is extracted mainly by the use of vents, and the act of extracting steam from a turbine system is needed for purposes like de-pressurization and multi-pressure application.

There is another term that bears similarity to extraction in steam turbines; bleeding.

The difference between bleeding and extraction in a steam turbine or any other fluid-based industrial system is that bleeding is a more spontaneous, uncontrolled loss of fluid, energy and/or pressure whereas extraction usually occurs under deliberate, controlled conditions.

Extraction turbines can be either extraction-back pressure or extraction-condensing turbine; which differ based on how fluid phase and pressure and controlled in the system.

5). Condensing Turbine (as one of the Types of Steam Turbines)

Condensing steam turbine is a type of steam turbine in which steam is condensed under controlled conditions, after it has been used to rotate the turbine and produce mechanical energy.

The purpose of using a condenser in steam turbine systems is to conserve water by converting exhaust steam to process water that can be fed into the boiler and reused.

This approach is most common in cases where industrial processes like electricity generation are being carried out using low-cost energy resources like waste biomass. It is also used in large-scale operations that require reliability and continuity.

The difference between condensing and non condensing steam turbines is the presence of a condenser in the former and its absence in the latter; so that process steam from condensing turbines is converted entirely to water, while in non-condensing turbines the steam is exhausted into an external system in which it is used as and energy source.

Non-condensing steam turbines are also called back pressure turbines, and can be viewed as a type of energy recovery system, where waste thermal energy of steam is conserved and re-used. On the other hand, condensing steam turbines can be viewed as a type of water conservation-turbine system.

6). Radial-Flow Turbine

Radial flow turbine is a type of turbine in which fluid flows along the radius of the turbine shaft.

A radial flow turbine works by capturing pressurized fluid in its casing, using a set of spiral-shaped runner blades and vanes, so that the fluid is forced toward the radius of the shaft as the turbine begins to rotate.

The working principle of the radial steam turbine is based on its spiral design, which is optimized to transfer maximum rotating power from the blades to the shaft.

Asides the radial flow type, there are other types of turbines that are classified based on fluid-flow direction. These include axial and tangential turbines, although the latter is less-commonly distinguished as a major turbine type.

The difference between axial and radial flow turbines is that axial flow turbines are designed to ensure that fluid flows along the axis of the shaft, thereby transferring maximum mechanical energy to the blades, while radial flow turbines are designed to maximize blade-to-shaft energy transfer by sustaining fluid flow along the shaft's radius.

The difference between tangential and radial flow turbines is that tangential flow turbines capture fluid at a tangent to the shaft and runner, while radial flow turbines capture fluid along the radius of the turbine shaft.

These different designs differ only slightly in overall performance, and are selected based on specific need.

An example of radial flow turbine is the Ljungström turbine, often used in power generation [1].

Types of Steam Turbines: Radial Flow Turbine (Credit: Girante_Francis.jpg 2011)

7). Axial-Flow (as one of the Types of Steam Turbines)

Axial flow steam turbine is a common type of steam turbine in which the working fluid flows parallel to the axis of the turbine shaft.

The axial flow turbine is more commonly-used than radial flow turbine, because it is simpler to design and maintain.

Examples of axial flow turbines include; Propeller and Kaplan Turbines [3].

Conclusion

Types of steam turbines are;

1. Impulse Turbine

2. Reaction

3. Back Pressure

4. Extraction

5. Condensing

6. Radial-Flow

7. Axial-Flow

References

1). Coronetta, U.; Enrico, S. (2020). "Optimal Design of a Ljungström Turbine for ORC Power Plants: From a 2D model to a 3D CFD Validation." International Journal of Turbomachinery Propulsion and Power 5(3):19. Available at: https://doi.org/10.3390/ijtpp5030019. (Accessed 2 March 2023).

2). Issa, M.; Ilinca, A.; Abbas, T. (2020). "Biomass Combined Heat and Power Generation for Anticosti Island: A Case Study." Available at: https://www.researchgate.net/publication/339944078_Biomass_Combined_Heat_and_Power_Generation_for_Anticosti_Island_A_Case_Study. (Accessed 2 March 2023).

3). Otutuama, O. M. (2020). "DESIGN AND FABRICATIONS OF A GRAVITATIONAL VORTEX HYDRAULIC TURBINE." Available at: https://doi.org/10.13140/RG.2.2.11358.66880. (Accessed 2 March 2023).

4). Scaife, W. G. (1985). "The Parsons Steam Turbine." Scientific American Vol. 252, No. 4 (April 1985), pp. 132-139. Available at: https://www.jstor.org/stable/24967620. (Accessed 2 March 2023).

5). Schilling, B. K.; Falvo, M. J.; Chiu, L. Z. (2008). "Force-velocity, impulse-momentum relationships: implications for efficacy of purposefully slow resistance training." J Sports Sci Med. 2008 Jun 1;7(2):299-304. Available at: https://www.semanticscholar.org/paper/Force-velocity%2C-impulse-momentum-relationships%3A-for-Schilling-Falvo/a7af7ef48b99c85563ee0d49a4bcdd7f55461ae6. (Accessed 2 March 2023).

6). Zaniewski, D.; Klimaszewski, P.; Witamowski, Ł.; Jędrzejewski, Ł.; Klonowicz, P.; Lampart, P. (2019). "Comparison of an impulse and a reaction turbine stage for an ORC power plant." Archives of Thermodynamics 40(3):137-157. Available at: https://doi.org/10.24425/ather.2019.129998. (Accessed 2 March 2023).