7 Types of Gasifiers and their Characteristics Explained

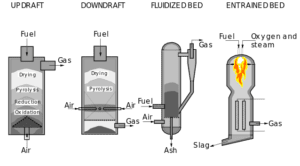

Types of gasifiers are; updraft, downdraft, crossdraft, circulating, bubbling, side-fed and top-fed gasifiers. They can be broadly grouped into three categories, which are; moving-bed, fluidized-bed, and entrained flow gasifiers.

This article discusses the types of gasifiers and their characteristics, as follows;

1). Updraft Gasifier (as one of the Types of Gasifiers)

Updraft gasifier is one of the most common and effective types of gasifiers.

It has a relatively simple design, and is broadly categorized under the moving-bed class of gasifiers, alongside downdraft and crossdraft types.

In updraft gasifier, the feedstock or ‘fuel’ is introduced such that it moves downward (toward the bottom of the gasifier), while the gasifying agent is introduced from the bottom, such that it ascends upward (toward the top of the gasifier) [7].

This arrangement ensures that the feedstock comes in close contact with the gasifying agent, which supplies heat energy for thermal conversion. It also allows for integrated pretreatment, which occurs in the form of drying as the feedstock first contacts heat while descending into the gasifier.

The updraft gasifier is known for its ease of operation as well as energy efficiency, and feedstock-conversion efficiency [1]. All forms of biomass can be treated using this type of gasifier.

2). Downdraft Gasifier

The downdraft gasifier is another type of moving-bed gasifier in which the feedstock and gasifying agent are both introduced so that they move downward (toward the bottom of the gasifier). Often, these two components are introduced concurrently.

One of the advantages of downdraft gasifier is high syngas yield.

This occurs because the downward movement of feedstock and gasifying agent allows the feedstock to breakdown effectively in the presence of large amount of heat.

Since the feedstock is continually subjected to high-temperature conditions, syngas produced in downdraft gasifier is usually of high purity, containing low amounts of tar [2].

The tar itself is mostly decomposed and transformed to gaseous material as already-formed product gases navigate toward the bottom of the reactor or gasifier under high temperature. In downdraft gasifier, product gases leave the system from the bottom.

3). Crossdraft Gasifier (as one of the Types of Gasifiers)

Crossdraft or cross-current gasifiers are not as common as updraft and downdraft types.

In a crossdraft gasifier, the feedstock is usually fed into the system from the top, while air is fed in from the side of the gasifier [5].

The purpose of this approach is to enable air flow in a cross-wise manner through the gasifier [3], thereby coming in full contact with the feedstock (or ‘fuel’) to facilitate thermal decomposition.

Based on the mode of introduction of air into the system, thermal decomposition in a crossdraft gasifier can be considered similar to the process of incineration.

Often, the gasifying agent is introduced from the bottom, so that it flows upward toward the feedstock in a manner similar to what occurs in an updraft gasifier. In some arrangements, however, the gasifying agent is fed in from the side.

In crossdraft gasification, the syngas and other product gases resulting from thermal decomposition are recovered from the side of the gasifier, rather than the bottom.

While the gasification products may not be as pure as in downdraft gasifiers, the crossdraft system is suitable for a limited range of complex, high-volume biomass, which cannot be easily treated using other gasifiers.

4). Circulating Gasifier

Circulating gasifier is type of fluidized bed gasifier which makes use of unidirectional gas pressure to create a rotary internal dynamic that helps heat from both external fuel and internally-generated biofuel, to circulate effectively within the system.

The circulating gasifier works by the introduction of gasifying agents under pressure into the system, so that they suspend the particles of the fuel (feedstock) while thermal decomposition takes place.

It derives its name ‘circulating’ from the thorough and cyclic pattern of mixing which typically occurs between the fuel particles and gasifying agent(s) in this type of gasifier.

Circulating gasifiers derive their efficiency from rapid flow and through mixing at high-temperature, all of which combine to facilitate high yield.

Because of the circulatory mechanism involved, effective recycling of both product gas and char is possible. This means that tar removal and char reduction occur, leading to high purity, high yield, as well as low residue, wastage and environmental degradation risk.

Energy conservation can be said to be achieved in a circulating gasifier because of the heat transfer from product gases to feedstock, which reduces the demand for heat from external sources.

Generally, fluidized bed gasification is one of the most suitable types of gasification for heterogeneous feedstock. The circulating gasifiers can simultaneously and effectively convert multiple types of biomass with varying characteristics, and is good for large-scale operations.

Feedstock needs to be in particulate form (can be pulverized to achieve this) in order to be fed into and converted by a circulating gasifier.

5). Bubbling Gasifier (as one of the Types of Gasifiers)

Bubbling gasifier (or bubbling-bed gasifier) is a type of fluidized bed gasifier in which a stream of pressurized gas is introduced into the system such that particles of the bed and feedstock are set into motion in a bubbling or reverberating mechanism.

The bed is usually made from inert materials like sand or alumina, and may also contain catalytic components like quicklime (CaO).

In bubbling bed gasifiers, the pressure of gasifying agents enable feedstock to undergo mixing and thermal decomposition. It also allows bioenergy from product gases to be recycled.

Bubbling bed gasification process can be described as sustainable and conservative, because the gasifier minimizes both energy waste and environmental impact. It is good for achieving uniform conversion and heat distribution [6].

6). Side-fed Gasifier

Side-fed gasifier is an entrained-flow gasifier in which the feedstock or fuel is introduced from the side of the reactor.

In side-fed gasifiers, the gasifying agent(s) is often introduced simultaneously, and may be fed through the same inlet as the fuel.

It is a relatively fast and efficient method, and may yield low amounts of impurities, although not as low as those produced when a downdraft gasifier is used.

7). Top-fed Gasifier (as one of the Types of Gasifiers)

In top-fed gasifiers, the fuel is fed into the system from the top, alongside the gasifying agent.

It operates similar to side-fed gasifiers, and utilizes less pressure and very high temperature to convert the feedstock.

Conclusion

The types of gasifiers are;

1. Updraft Gasifier

2. Downdraft Gasifier

3. Crossdraft Gasifier

4. Circulating Gasifier

5. Bubbling Gasifier

6. Side-fed Gasifier

7. Top-fed Gasifier

References

1). Adi, S.; Vidian, F.; Nugroho, Y. (2014). “Experimental Gasification of Biomass in an Updraft Gasifier with External Recirculation of Pyrolysis Gases.” Journal of Combustion 2014(31). Available at: https://doi.org/10.1155/2014/832989. (Accessed 8 October 2022).

2). Havilah, P. R.; Sharma, A. K.; Govindasamy, G.; Matsakas, L.; Patel, A. (2022). “Biomass Gasification in Downdraft Gasifiers: A Technical Review on Production, Up-Gradation and Application of Synthesis Gas.” Energies 2022, 15(11), 3938. Available at: https://doi.org/10.3390/en15113938. (Accessed 10 October 2022).

3). Kar, T.; Keles, S. (2019). “Hydrogen production from renewables: Biomass.” Available at: https://www.researchgate.net/publication/339314676_Hydrogen_production_from_renewables_Biomass. (Accessed 9 October 2022).

4). Li, &.; Grace, J.; Lim, J. C.; Watkinson, P.; Chen, H. P.; Kim, J. R. (2004). “Biomass gasification in a circulating fluidized bed.” Biomass and Bioenergy 26(2):171-193. Available at: https://doi.org/10.1016/S0961-9534(03)00084-9. (Accessed 9 October 2022).

5). Mai, P. T.; Nguyen, Q. D. (2020). “Gasification of Biomass.” Available at: https://doi.org/10.5772/intechopen.93954. (Accessed 10 October 2022).

6). Monteiro, E.; Couto, N. D.; Rouboa, A.; Silva, V.; Bouziane, K. (2013). “Influence of the Biomass Gasification Processes on the Final Composition of Syngas.” Energy Procedia 36. Available at: https://doi.org/10.1016/j.egypro.2013.07.068. (Accessed 9 October 2022).

7). Vigouroux, R. A. Z.; Suarez, J. A.; Diaz, P. R. R. (2003). “Updraft Gasification.” Fifth Latin-American Congress on Electricity Generation and Transmission, 5th CLAGTEE, São Pedro, Brazil. Available at: https://www.researchgate.net/publication/267737266_Updraft_Gasification. (Accessed 8 October 2022).