5 Causes of Corrosion and Their Influence(s) Explained

Causes of corrosion are; high humidity (and temperature), mechanical stress, acidic ambient media, uncoated and irregular metal surfaces, high conductivity and electrochemical potential.

This article discusses the causes of corrosion and their various influences, as follows;

1). High Humidity (as one of the Causes of Corrosion)

One of the most common and effective causes of corrosion is high humidity.

The rate of corrosion generally increases with the level of humidity of the surrounding or medium in which a metal occurs.

There are multiple explanations that can be given with regards to the relationship between humidity and corrosion.

One of these is that humid air is rich in hydrogen and oxygen ions, both of which are essential reactants in corrosive deterioration processes for solid-state metals.

A second explanation would include the obvious fact that humid air contains significant quantity of water, which may condense on the surface of the metal and facilitate both hydration and oxidation reactions.

The role of water in corrosion is easily detectable by observing the increased rate of rusting (which is a form of corrosion) of iron and its alloys when stored or abandoned under humid conditions. In fact, such humid-storage-related corrosion is a common cause of damage, degradation and loss of efficiency of equipment and machinery.

Because humidity enhances corrosion rate and severity, it is recommendable as part of measures for prevention of corrosion, for metallic materials to be stored under relatively-dry conditions and/or treated with drying agents on a routine basis.

As a cause of corrosion, high humidity is influential on its own, and can corrode metals independent of any other facilitative condition.

However, high humidity corrosion is often accompanied and aggravated by high temperature.

This explains why humid air is more corrosive when its is warm.

High temperature increases the rate of rusting of metals because it enhances the reactivity of oxygen and hydrogen ions with metals; thereby increasing electron transfer and oxidation; which result in corrosion.

In electrolytic corrosion, higher temperature is accompanied by faster rate of electron-diffusion and electrolyte resistance; so that a metal placed in such electrolyte loses its weight faster due to corrosion [6].

When discussing high temperature as a cause of corrosion, it is important to outline the difference between high temperature-driven corrosion processes, and high-temperature corrosion; which is a chemical attack from molten salts, metals or gases at high temperatures exceeding 400°C [7].

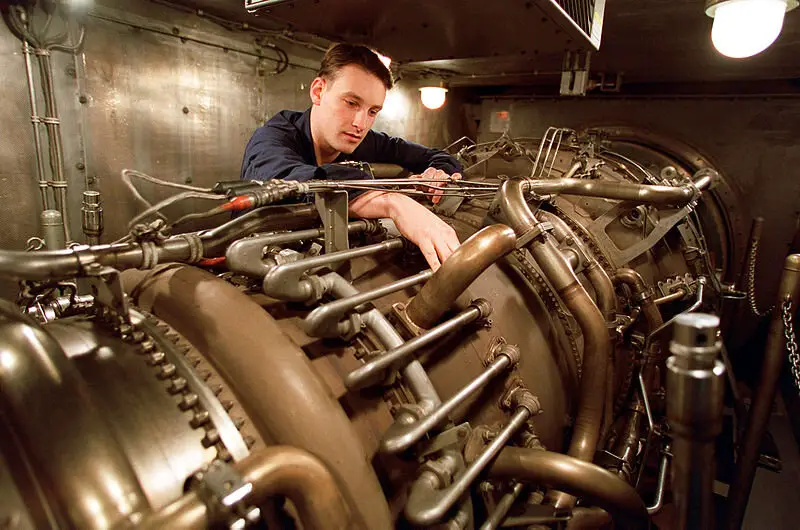

High-temperature corrosion is caused by the presence of acidic media like gases and molten materials in close proximity to a metal, at extremely high temperature. It is more common in metals that are part of thermal and thermoelectric systems including gas turbines, furnaces and generator engines.

While it is essentially a kind of corrosion, temperature levels must not always be extreme as in high-temperature corrosion, in order to cause the deterioration of metals. Any notable amount of heat can increase corrosion rate, especially when this is accompanied by notable humidity.

2). Mechanical Stress

Stress does not cause corrosion independently or directly; but rather acts as a facilitator that triggers the commencement and/or acceleration of corrosion.

Mechanical stress affects the rate of corrosion of metals in a directly-proportional manner; meaning that high stress levels are associated with faster corrosion rates.

Observations of corrosion caused by stress are often made in engineering structures and facilities that are subject to significant levels of operational, mechanical load.

As a result of the context(s) in which it tends to occur, stress is perhaps the most consequential factor in corrosion.

Stress acts as a facilitator of increased deterioration in terms of both speed and severity. Some types of corrosion such as intergranular (corrosion) tend to become much faster and more severe in the presence of mechanical load [5].

Stress corrosion cracking (SCC) is a process of fracturing that is induced by mechanical stress, and is relatively-common in pipelines made from iron alloys. Although the commencement of such corrosion is induced by stress, its procession is a chemical process involving reactive deterioration of the metal [4].

3). Acidic Ambient Media (as one of the Causes of Corrosion)

Acidity affects corrosion in a directly-proportional manner; meaning that higher acidity (lower pH) is associated with faster rate of corrosion, and vice-versa.

Studies have shown that higher concentration of acidic gases or liquids in a medium increases the rate and severity of corrosion [8].

Corrosion takes place in acidic media as a result of high concentration of hydrogen ions for electrochemical (redox) reactions. These reactions are what lead to the deterioration of metals placed under acidic conditions.

The role of acidity in corrosion can be observed in multiple contexts. These contexts extend beyond metals to concrete and rock materials, which are known to corrode when exposed to acid rain or acidic air-moisture.

In refineries, acidic conditions are common, and act as a major driver of equipment corrosion and damage [2].

Control of acid-induced or -enhanced corrosion is possible through diverse means, including the use of plant biomass in the form of agricultural waste [9].

4). Uncoated and Irregular Metal Surfaces

The difference between coated and uncoated steel is the presence and absence of an extra layer of material (metallic or non-metallic) over the surface of the steel material.

For all metals, the presence of a layer of surface-coating implies that corrosion rate will be slower than for unprotected metals.

Uncoated steel will rust at a more rapid rate than coated steel, especially if the steel is mild; and contains a relatively-low amount of carbon.

Often, the coating material is either water-resistant paint or corrosion-resistant metal. Absence of these materials makes the metal more vulnerable to surface corrosion.

Surface corrosion of metal is progressive deterioration that commences from the exposed surface. Asides the absence of protective coating, another contributor to surface corrosion is irregularity, which can enhance localized, lateral deterioration in many metals [3].

In general, physical factors influencing corrosion include surface morphology, texture, and presence or absence of defects [1].

5). High Conductivity and Electrochemical Potential (as one of the Causes of Corrosion)

Both conductivity and electrochemical potential (ECP) are directly proportional to the rate and severity of corrosion. This means that higher conductivity and electrochemical potential are generally associated with more-rapid and severe deterioration of metals.

Conductivity affects corrosion by influencing how electrons are lost by the metal in an oxidation reaction. Since oxidation is a core component of corrosion, high conductivity leads to high efficiency of the corrosion process.

It must be noted that discussions of conductivity in the context of corrosion refer to both metallic and electrolytic conductivities.

Corrosion is influenced by conductivity because it is an electrochemical process [10]. High conductivity equates to high electrochemical potential as the latter depends on how freely electrons can navigate between a metal and its ambient medium.

Reducing the conductivity of the ambient medium is possible through acidity reduction, which can be achieved by protecting a metal from highly-saline water in marine environments, or acidic gases in oil and gas facilities. Such protection is achievable through galvanization or 'coating'.

These analogies show how the various causes of corrosion and their possible mitigative methods, are related.

Conclusion

Causes of corrosion are;

1. High Humidity

2. Mechanical Stress

3. Acidic Ambient Media

4. Uncoated and Irregular Metal Surfaces

5. High Conductivity and Electrochemical Potential

References

1). Dwivedi, D.; Lepkova, K.; Becker, T. (2017). "Carbon steel corrosion: a review of key surface properties and characterization methods." RSC Advances 7(8):4580-4610. Available at; https://doi.org/10.1039/C6RA25094G. (Accessed 13 May 2023).

2). Golshani, Z.; Arjmand, F.; Amiri, M.; Hosseini, S. M. A.; Fatemi, S. J. (2023). "Investigation of Dracocephalum extract based on bulk and nanometer size as green corrosion inhibitor for mild steel in different corrosive media." Sci Rep. 2023 Jan 17;13(1):913. Available at: https://doi.org/10.1038/s41598-023-27891-y. (Accessed 13 May 2023).

3). Hacıibrahimoğlu, M. Y.; Bedir, M.; Yavuz, A. (2016). "Structural and Corrosion Study of Uncoated and Zn-Cu Coated Magnesium-Based Alloy." Metals 2016, 6, 322. Available st: https://doi.org/10.3390/met6120322. (Accessed 13 May 2023).

4). Khalifeh, A. (2020). "Stress Corrosion Cracking Behavior of Materials." Engineering Failure Analysis. Available at: https://doi.org/10.5772/intechopen.90893. (Accessed 13 May 2023).

5). Li, L.; Li, C-Q.; Mahmoodian, M. (2019). "Effect of Applied Stress on Corrosion and Mechanical Properties of Mild Steel." Journal of Materials in Civil Engineering 31(2). Available at: https://doi.org/10.1061/(ASCE)MT.1943-5533.0002594. (Accessed 13 May 2023).

6). Li, Q.; Zhang, Y.; Cheng, Y.; Zuo, X.; Wang, Y.; Yuan, X.; Huang, H. (2022). "Effect of Temperature on the Corrosion Behavior and Corrosion Resistance of Copper-Aluminum Laminated Composite Plate." Materials (Basel). 2022 Feb 21;15(4):1621. Avail at: https://doi.org/10.3390/ma15041621. (Accessed 13 May 2023).

7). Pedeferri, P. (2018). "High Temperature Corrosion." Corrosion Science and Engineering (pp.589-610). Available at: https://doi.org/10.1007/978-3-319-97625-9_26. (Accessed 13 May 2023).

8). Samosir, R.; Simanjuntak, S. L. M. (2017). 'The influence of concentration and pH on corrotion rate in stainless steels – 316 solution HNO3 medium." IOP Conference Series: Materials Science and Engineering, Volume 237, 1st Nommensen International Conference on Technology and Engineering 11–12 July 2017, Medan, Indonesia. Available at: https://doi.org/10.1088/1757-899X/237/1/012047. (Accessed 13 May 2023).

9). Saxena, A.; Prasad, D.; Haldhar, R. (2018). "Investigation of corrosion inhibition effect and adsorption activities of Cuscuta reflexa extract for mild steel in 0.5 M H 2 SO 4." Bioelectrochemistry (Amsterdam, Netherlands) 124. Available at: https://doi.org/10.1016/j.bioelechem.2018.07.006. (Accessed 13 May 2023).

10). Wang, J.; Wang, J.; Han, E-H. (2015). "Influence of Conductivity on Corrosion Behavior of 304 Stainless Steel in High Temperature Aqueous Environment." Journal of Materials Science and Technology -Shenyang- 32(4). Available at: https://doi.org/10.1016/j.jmst.2015.12.008. (Accessed 13 May 2023).